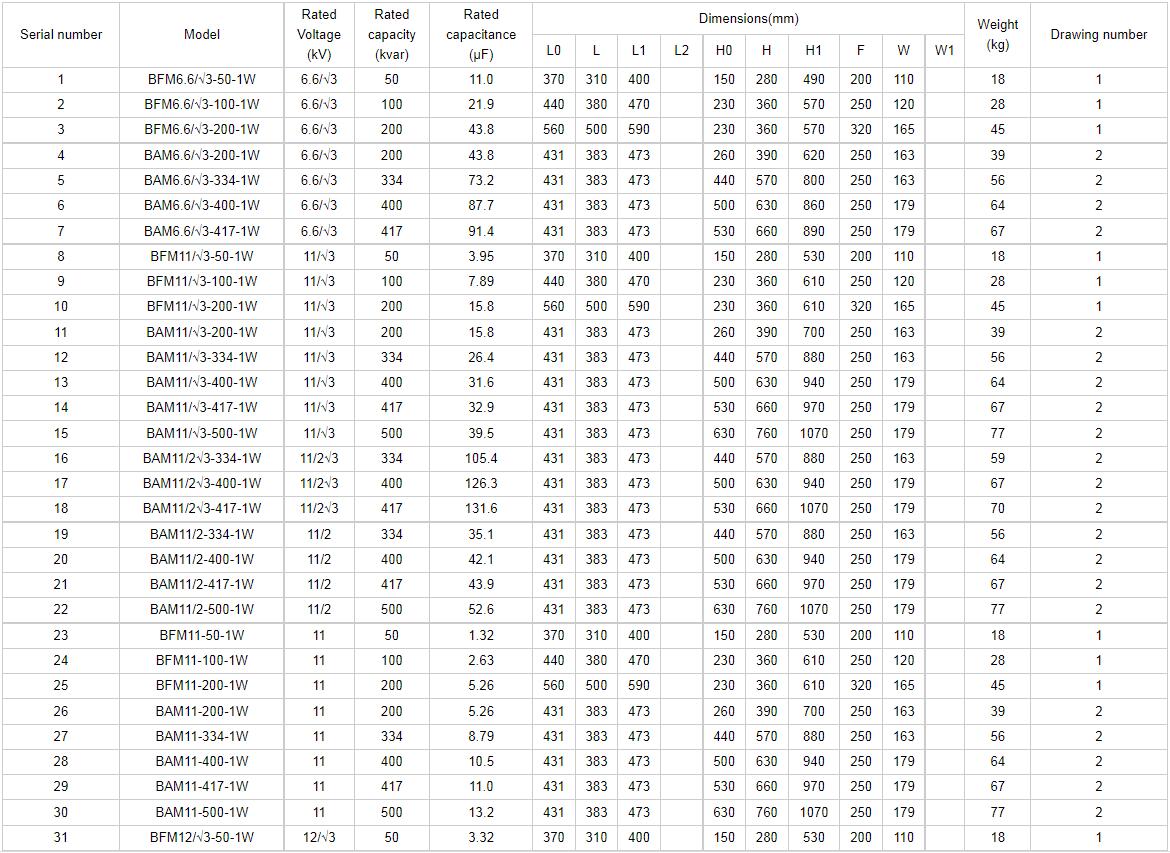

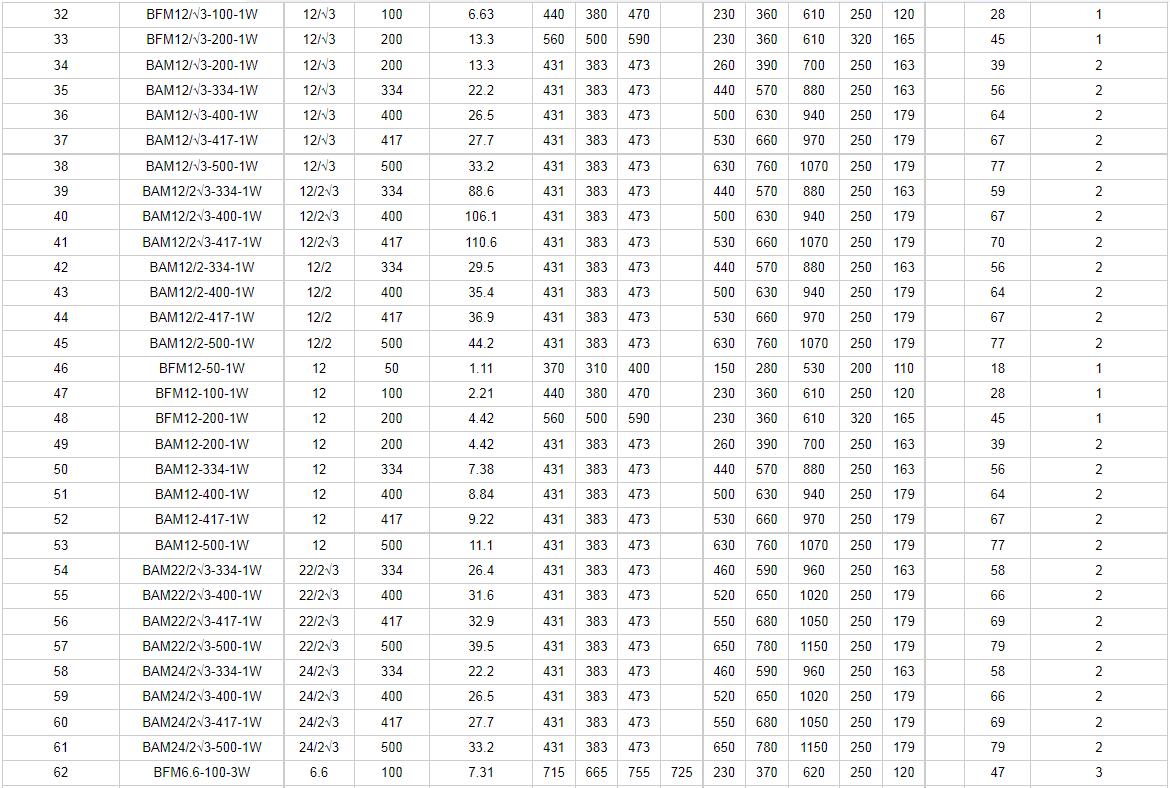

The main technical parameters : Rated voltage: 6.3kV, 6.6kV, 6.6√3kV, 10.5kV, 11kV, 11√3kV, 12kV, 12√3kV, 19kV, etc.; Rated capacity: 30~400kvar, other voltage levels and capacities can be specially ordered. Capacity tolerance: -5%~+10%; Loss tangent value: film-paper composite medium tanδ≤0.08%, full-film medium tanδ≤0.05%; Withstand voltage: The capacitors should be able to withstand AC 2.15 times or DC 4.3 times the rated voltage, and there will be no breakdown or flashover for 10s; Insulation level: 6kV level 30kV, 10kV level 42kV AC test lasted for 1min without breakdown or flashover. Self-discharge performance: a capacitor with a discharge resistance inside, the residual voltage drops from 2Un peak value to below 75V within 10min after power off; Maximum allowable overvoltage: 1.1 times the rated voltage, no more than 8 hours per 24 hours, 1.15 times the rated voltage, no more than 30 minutes per 24 hours, 1.2 times the rated voltage, no more than 5 minutes. 1.3 times the amount No more than 1 minute at constant voltage. Maximum allowable current: The allowable current does not exceed .3 times the rated current to operate, and the transient overcurrent considers the overvoltage, the positive deviation of the capacitor and the influence of harmonics, which should not exceed 1.43 times the rated current. Compliance with standards: The product complies with the international GB/T 11024.1-2009 and the international IEC60871-1:2005.

The main technical parameters : Rated voltage: 6.3kV, 6.6kV, 6.6√3kV, 10.5kV, 11kV, 11√3kV, 12kV, 12√3kV, 19kV, etc.; Rated capacity: 30~400kvar, other voltage levels and capacities can be specially ordered. Capacity tolerance: -5%~+10%; Loss tangent value: film-paper composite medium tanδ≤0.08%, full-film medium tanδ≤0.05%; Withstand voltage: The capacitors should be able to withstand AC 2.15 times or DC 4.3 times the rated voltage, and there will be no breakdown or flashover for 10s; Insulation level: 6kV level 30kV, 10kV level 42kV AC test lasted for 1min without breakdown or flashover. Self-discharge performance: a capacitor with a discharge resistance inside, the residual voltage drops from 2Un peak value to below 75V within 10min after power off; Maximum allowable overvoltage: 1.1 times the rated voltage, no more than 8 hours per 24 hours, 1.15 times the rated voltage, no more than 30 minutes per 24 hours, 1.2 times the rated voltage, no more than 5 minutes. 1.3 times the amount No more than 1 minute at constant voltage. Maximum allowable current: The allowable current does not exceed .3 times the rated current to operate, and the transient overcurrent considers the overvoltage, the positive deviation of the capacitor and the influence of harmonics, which should not exceed 1.43 times the rated current. Compliance with standards: The product complies with the international GB/T 11024.1-2009 and the international IEC60871-1:2005.

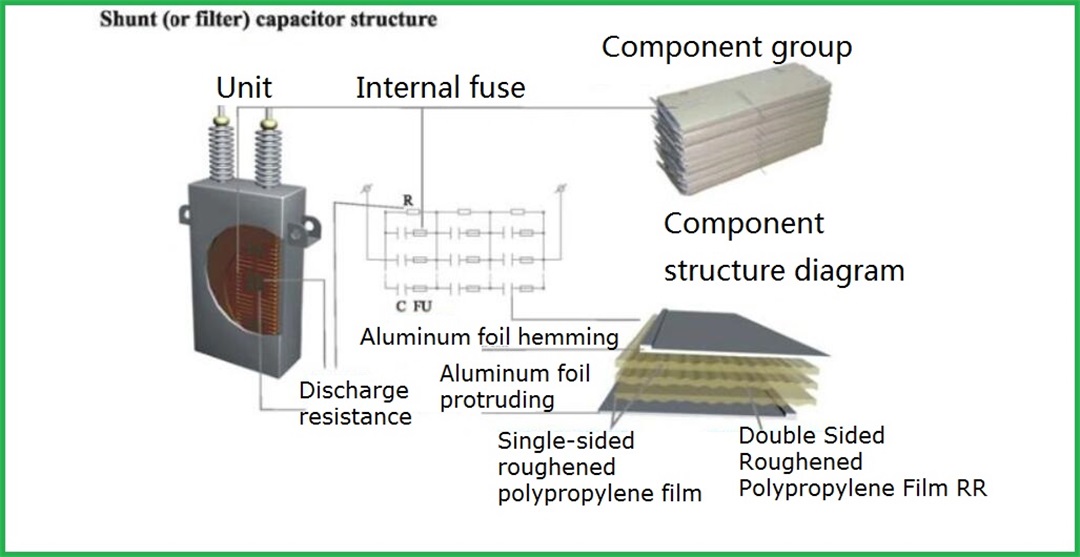

The capacitor is composed of a box shell and a core. The box shell is made of thin steel plate by sealing and welding. The box shell is welded with an outlet porcelain sleeve. The two sides of the box wall are welded with hangers for installation, and one side of the hangers is equipped with grounding bolts. The capacitor core is formed by laminating several components and insulating parts, and the components are formed by rolling and flattening two sheets of aluminum foil sandwiched paper composite medium or full film medium as polar plates. The components in the core are connected in a certain series and parallel mode to meet the requirements of different voltages and capacities. Capacitors with internal fuses, each component has a fuse in series. When a component breaks down, the intact component connected in parallel with it will discharge it, so that the fuse will be quickly blown in milliseconds, and the faulty component will be blown out. cut off, allowing the capacitor to continue to operate. Three-phase capacitors are star-connected. The liquid medium in the capacitor is used to impregnate the solid medium and fill the voids inside the capacitor. It has excellent electrical and physical properties and has good compatibility with other materials in the capacitor. Working conditions: The altitude does not exceed 1000m, the ambient temperature is -40/B, and the maximum temperature of Class B is +45℃. The installation site has no severe mechanical vibration, no harmful gas and steam, no conductive or explosive dust. Capacitors should be guaranteed to operate under good ventilation conditions, and are not allowed to operate under closed and unventilated conditions. The wiring of capacitors should be flexible conductors, and the whole circuit should be in good contact.

The capacitor is composed of a box shell and a core. The box shell is made of thin steel plate by sealing and welding. The box shell is welded with an outlet porcelain sleeve. The two sides of the box wall are welded with hangers for installation, and one side of the hangers is equipped with grounding bolts. The capacitor core is formed by laminating several components and insulating parts, and the components are formed by rolling and flattening two sheets of aluminum foil sandwiched paper composite medium or full film medium as polar plates. The components in the core are connected in a certain series and parallel mode to meet the requirements of different voltages and capacities. Capacitors with internal fuses, each component has a fuse in series. When a component breaks down, the intact component connected in parallel with it will discharge it, so that the fuse will be quickly blown in milliseconds, and the faulty component will be blown out. cut off, allowing the capacitor to continue to operate. Three-phase capacitors are star-connected. The liquid medium in the capacitor is used to impregnate the solid medium and fill the voids inside the capacitor. It has excellent electrical and physical properties and has good compatibility with other materials in the capacitor. Working conditions: The altitude does not exceed 1000m, the ambient temperature is -40/B, and the maximum temperature of Class B is +45℃. The installation site has no severe mechanical vibration, no harmful gas and steam, no conductive or explosive dust. Capacitors should be guaranteed to operate under good ventilation conditions, and are not allowed to operate under closed and unventilated conditions. The wiring of capacitors should be flexible conductors, and the whole circuit should be in good contact.

The selection of the rated voltage of the capacitor must be based on the network voltage. Considering that the input of the capacitor will increase the voltage, so when selecting the rated voltage of the capacitor, it is at least 5% higher than the network voltage ; when there is a reactor in the capacitor circuit, the terminal voltage of the capacitor The ground increases with the reactance rate of the reactor in series, so when selecting the rated voltage of the capacitor, it should be determined after calculation according to the reactance rate of the reactor in the string. Capacitors are low-impedance channels of harmonics. Under harmonics, a large amount of harmonics will be injected into the capacitors to make the capacitors overcurrent or overvoltage. In addition, the capacitors will amplify the harmonics and cause resonance when they expire, endangering the safety of the power grid and making the capacitors lifespan. Therefore, capacitors with large harmonics must be used under reactors that suppress harmonics. The inrush current when the capacitor is closed can be as high as hundreds of times of the rated current of the capacitor. Therefore, the switch for switching the capacitor should choose a switch without re-breakdown. In order to suppress the closing inrush current, a reactor that suppresses the inrush current can also be connected in series. After the capacitor with internal discharge resistance is disconnected from the power supply, it can drop from the peak value of the rated voltage to below 75V within 10 minutes . be explained when. Capacitors used for line compensation should be installed at 150~200kvar in one place, and be careful not to install the capacitors on the same stage as the transformer, and do not use the same group of dropouts to prevent overshooting caused by ferromagnetic resonance when the line is not running in all phases. Current overvoltage can damage capacitors and transformers. The zinc oxide surge arrester for the protection of operating overvoltage should be selected for the zinc oxide surge arrester dedicated to the capacitor, and it is best to install it between the capacitor poles. The fuse specially used for capacitor is selected for quick-break, and the rated current should be selected according to to 1.42~1.5 times of the rated current of the capacitor. When the capacitor is directly connected to the high-voltage motor in parallel, in order to prevent self-excitation when the motor is disconnected from the power supply, causing the voltage of the capacitor terminal to rise greater than the rated value, the rated current of the capacitor must be less than 90% of the no-load current of the motor; When using Y/△ wiring, it is not allowed to connect the capacitor directly to the motor in parallel, and a special wiring method should be adopted. When the capacitor is used at an altitude higher than 1000 meters or the capacitor is used in the humid tropical zone, it should be stated when ordering. Special spe certifications or special requirements for capacitors should be specified when ordering.

The selection of the rated voltage of the capacitor must be based on the network voltage. Considering that the input of the capacitor will increase the voltage, so when selecting the rated voltage of the capacitor, it is at least 5% higher than the network voltage ; when there is a reactor in the capacitor circuit, the terminal voltage of the capacitor The ground increases with the reactance rate of the reactor in series, so when selecting the rated voltage of the capacitor, it should be determined after calculation according to the reactance rate of the reactor in the string. Capacitors are low-impedance channels of harmonics. Under harmonics, a large amount of harmonics will be injected into the capacitors to make the capacitors overcurrent or overvoltage. In addition, the capacitors will amplify the harmonics and cause resonance when they expire, endangering the safety of the power grid and making the capacitors lifespan. Therefore, capacitors with large harmonics must be used under reactors that suppress harmonics. The inrush current when the capacitor is closed can be as high as hundreds of times of the rated current of the capacitor. Therefore, the switch for switching the capacitor should choose a switch without re-breakdown. In order to suppress the closing inrush current, a reactor that suppresses the inrush current can also be connected in series. After the capacitor with internal discharge resistance is disconnected from the power supply, it can drop from the peak value of the rated voltage to below 75V within 10 minutes . be explained when. Capacitors used for line compensation should be installed at 150~200kvar in one place, and be careful not to install the capacitors on the same stage as the transformer, and do not use the same group of dropouts to prevent overshooting caused by ferromagnetic resonance when the line is not running in all phases. Current overvoltage can damage capacitors and transformers. The zinc oxide surge arrester for the protection of operating overvoltage should be selected for the zinc oxide surge arrester dedicated to the capacitor, and it is best to install it between the capacitor poles. The fuse specially used for capacitor is selected for quick-break, and the rated current should be selected according to to 1.42~1.5 times of the rated current of the capacitor. When the capacitor is directly connected to the high-voltage motor in parallel, in order to prevent self-excitation when the motor is disconnected from the power supply, causing the voltage of the capacitor terminal to rise greater than the rated value, the rated current of the capacitor must be less than 90% of the no-load current of the motor; When using Y/△ wiring, it is not allowed to connect the capacitor directly to the motor in parallel, and a special wiring method should be adopted. When the capacitor is used at an altitude higher than 1000 meters or the capacitor is used in the humid tropical zone, it should be stated when ordering. Special spe certifications or special requirements for capacitors should be specified when ordering.