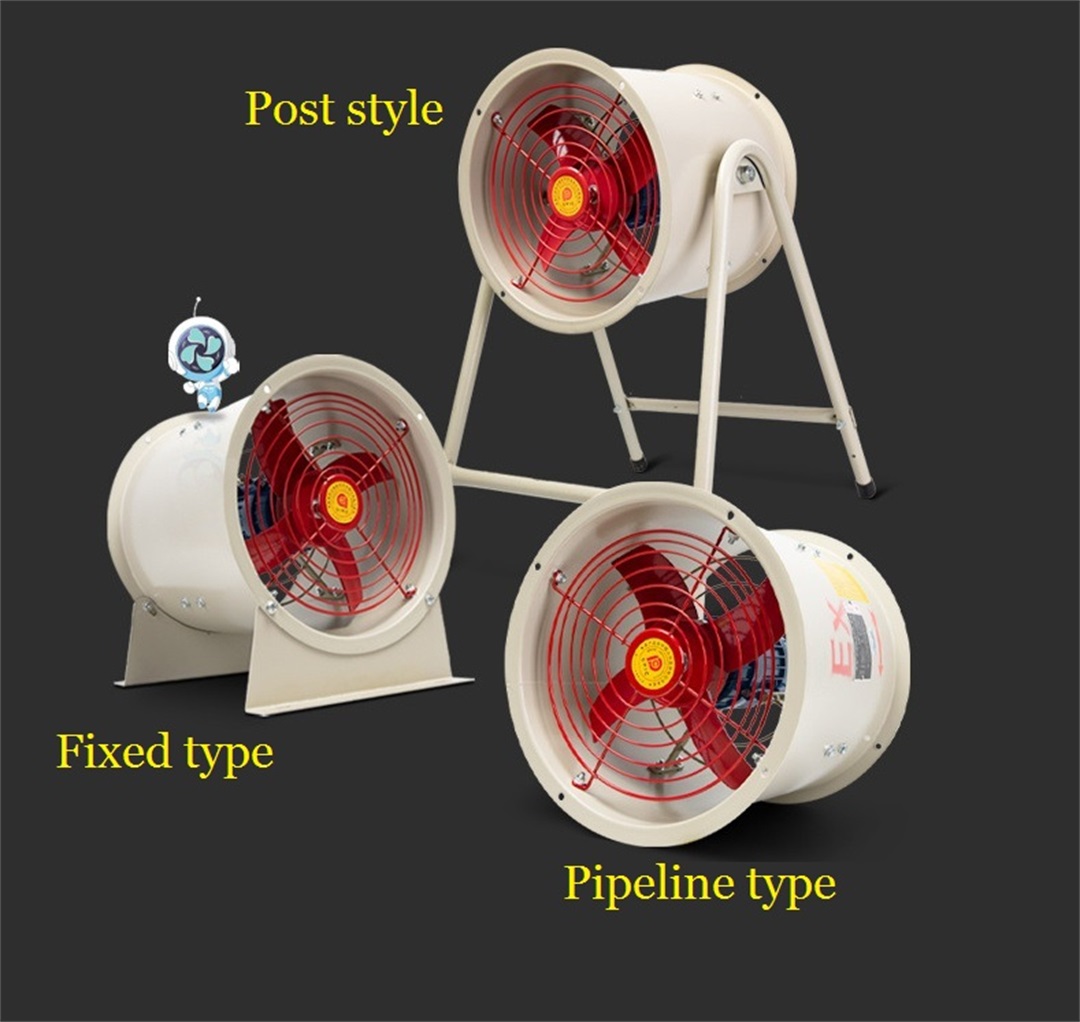

Features: 1. The explosion-proof fan has the same function as the ordinary fan. Explosion-proof refers to obtaining the explosion-proof certification stipulated by the state. Explosion-proof fans must use explosion-proof motors. 2. The flow channel components (impeller, casing, etc.) of the explosion-proof fan must be made of soft and hard materials. In general, the rotating parts and the fixed parts should adopt a soft and a hard way to prevent the friction or collision between the parts from generating sparks in the event of failure. Commonly used materials are 2a01 duralumin for impeller blades and blade rivets, and galvanized steel or glass fiber reinforced plastic for the shell. 3. The performance indicators listed in the performance table of explosion-proof fans are all valid ranges. It is divided into five performance points according to the air volume. The choice depends on the performance table. The error of the total pressure value of the qualified products of the factory fire-fighting fan under the rated air volume shall not exceed ±5%. The performance selection table is for performance under standard conditions and is not affected by technical documentation and order requirements. 4. The bracket is welded by steel pipe and angle iron. The blade is made of hot rolled steel. After static balance calibration, it runs smoothly, with low vibration and low noise. 5. The shell adopts epoxy anti-corrosion coating, and the motor adopts special anti-corrosion motor, which is used to transport corrosive gas. Explosion-proof axial flow fans are used to transport flammable and explosive gases. The impeller is made of aluminum alloy, and no sparks are generated during operation. The motor adopts explosion-proof motor. 6. The mesh cover is made of φ5/mm steel wire rope spot welding, which is sturdy and beautiful. 7. The bracket adopts high-frequency welded pipe, which is convenient and stable to use. Applicable environment: 1. Applicable to Zone 1 and Zone 2 of explosive gas environment; 2. Applicable to Class IIA and IIB explosive gas environments; 3. Applicable to environments with temperature group T1~T4; 4. Applicable to petroleum refining, storage, chemical industry , medical, military and military facilities and other explosive hazardous environments; 5. The product is mainly used for ventilation and cooling. Fan installation instructions: 1. Before installation, check in detail whether the fan is damaged or deformed. If there is damage and deformation, it can be installed after proper repair. 2. When installing, pay attention to check whether the inferior parts are loose, and the gap between the blade and the air duct should be uniform and not collide. 3. The weight of the duct connecting the tuyere should not be borne by the duct of the fan, and additional support should be added during installation. 4. A collector must be installed at the tuyere end of the fan, and a protective net must be installed. 5. The base of the fan must be naturally connected with the ground plane, and the base must not be knocked forcibly connected to prevent the base from being deformed. During installation, the base should be adjusted, shims should be added, and the horizontal position should be maintained, and then the anchor bolts should be tightened. 6. After the installation is completed, the experiment must be carried out first, and the official use is allowed only after the operation is normal.

Features: 1. The explosion-proof fan has the same function as the ordinary fan. Explosion-proof refers to obtaining the explosion-proof certification stipulated by the state. Explosion-proof fans must use explosion-proof motors. 2. The flow channel components (impeller, casing, etc.) of the explosion-proof fan must be made of soft and hard materials. In general, the rotating parts and the fixed parts should adopt a soft and a hard way to prevent the friction or collision between the parts from generating sparks in the event of failure. Commonly used materials are 2a01 duralumin for impeller blades and blade rivets, and galvanized steel or glass fiber reinforced plastic for the shell. 3. The performance indicators listed in the performance table of explosion-proof fans are all valid ranges. It is divided into five performance points according to the air volume. The choice depends on the performance table. The error of the total pressure value of the qualified products of the factory fire-fighting fan under the rated air volume shall not exceed ±5%. The performance selection table is for performance under standard conditions and is not affected by technical documentation and order requirements. 4. The bracket is welded by steel pipe and angle iron. The blade is made of hot rolled steel. After static balance calibration, it runs smoothly, with low vibration and low noise. 5. The shell adopts epoxy anti-corrosion coating, and the motor adopts special anti-corrosion motor, which is used to transport corrosive gas. Explosion-proof axial flow fans are used to transport flammable and explosive gases. The impeller is made of aluminum alloy, and no sparks are generated during operation. The motor adopts explosion-proof motor. 6. The mesh cover is made of φ5/mm steel wire rope spot welding, which is sturdy and beautiful. 7. The bracket adopts high-frequency welded pipe, which is convenient and stable to use. Applicable environment: 1. Applicable to Zone 1 and Zone 2 of explosive gas environment; 2. Applicable to Class IIA and IIB explosive gas environments; 3. Applicable to environments with temperature group T1~T4; 4. Applicable to petroleum refining, storage, chemical industry , medical, military and military facilities and other explosive hazardous environments; 5. The product is mainly used for ventilation and cooling. Fan installation instructions: 1. Before installation, check in detail whether the fan is damaged or deformed. If there is damage and deformation, it can be installed after proper repair. 2. When installing, pay attention to check whether the inferior parts are loose, and the gap between the blade and the air duct should be uniform and not collide. 3. The weight of the duct connecting the tuyere should not be borne by the duct of the fan, and additional support should be added during installation. 4. A collector must be installed at the tuyere end of the fan, and a protective net must be installed. 5. The base of the fan must be naturally connected with the ground plane, and the base must not be knocked forcibly connected to prevent the base from being deformed. During installation, the base should be adjusted, shims should be added, and the horizontal position should be maintained, and then the anchor bolts should be tightened. 6. After the installation is completed, the experiment must be carried out first, and the official use is allowed only after the operation is normal.