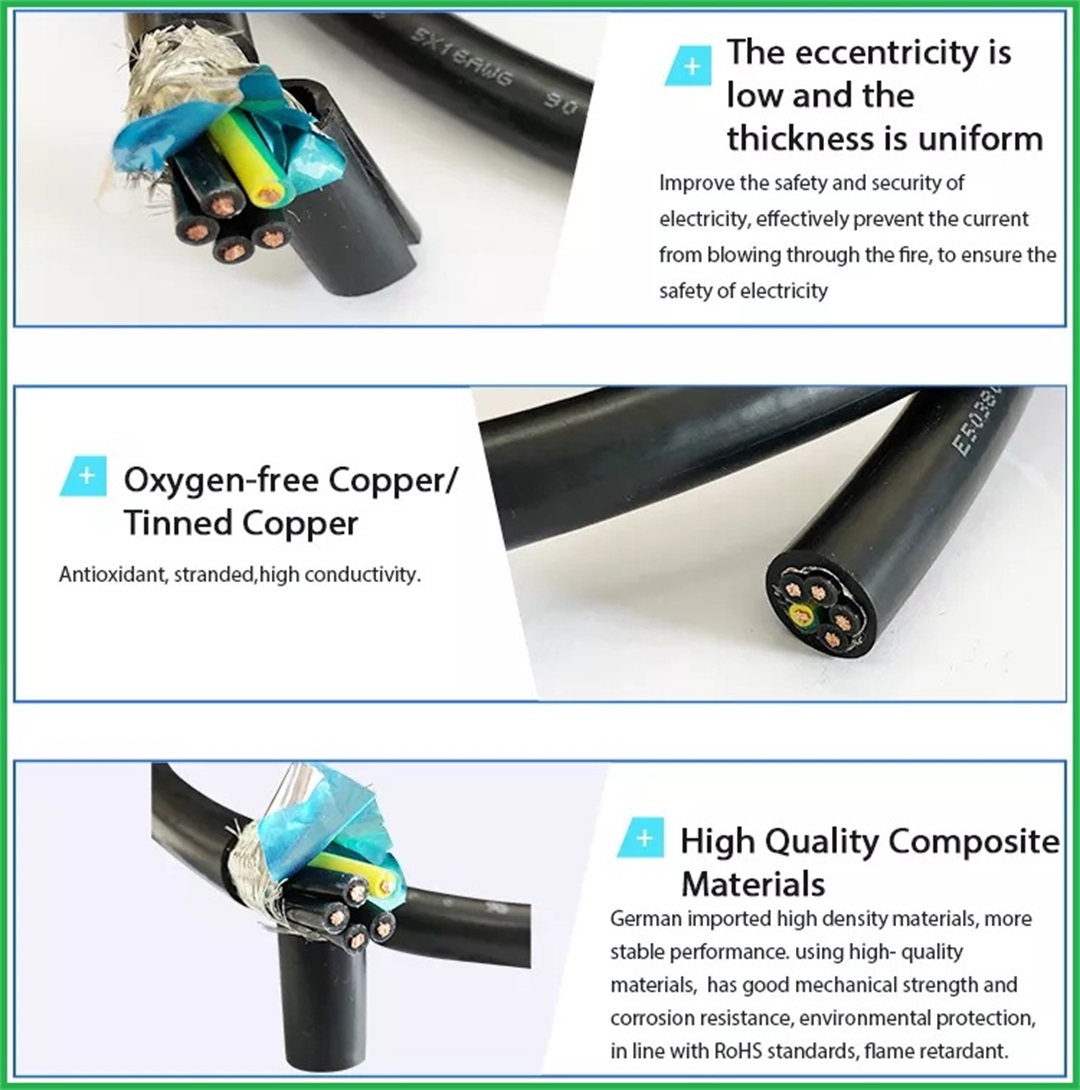

Due to the high conductivity and high mechanical strength of copper conductors, power cables often use copper as the conductor core material. In order to improve the conductivity of conductors and prevent electrochemical corrosion, single conductor wires are often tinned to become tinned copper wires. The cable conductor can be divided into compact and non compact type according to the manufacturing process. The compact cable conductor can save materials and reduce costs, but a single conductor is no longer a regular circle. In addition to conductors with small cross section, cable conductors are usually stranded structures, which can ensure high flexibility and strong flexibility of cables, and are not prone to insulation damage and plastic deformation. From the appearance of the cable, the stranded conductor can be divided into sector, circle, hollow circle, etc. According to the number of cable conductor cores, cables can also be divided into single core cables and multi-core cables. The insulation quality and level of power cables play a decisive role in the structure of the service life of cables. Marine power cables are classified according to the commonly used insulation types. Cable filling and shielding layer The gap between the multi-core cable cores must be filled with materials (such as non hygroscopic materials), which can not only separate the filler from the sheath, but also extrude the filler and the sheath into a whole, and can also wrap the non hygroscopic tape between the core and the sheath. In addition, there is a shielding layer inside the cable to optimize the electric field distribution inside the cable. The cable conductor is usually twisted by multiple wires. There must be a gap between the conductor and the insulation layer, and the local electric field will be concentrated. Setting an internal shielding layer between the conductor and the insulation layer can effectively solve this problem and prevent partial discharge between the core and the insulation layer. The external shielding layer is set between the insulation layer and the sheath to make the potential between the sheath and the shielding layer equal, and the contact between the insulation layer and the shielding layer is good, so as to avoid partial discharge. Cable sheath The protective layer of power cable is generally divided into two types: non-metallic and metal armored protective layer. The protective layer of the cable is mainly used to prevent mechanical damage to the cable, and to avoid the impact of environmental factors such as oil, salt and moisture on the cable insulation layer.

Due to the high conductivity and high mechanical strength of copper conductors, power cables often use copper as the conductor core material. In order to improve the conductivity of conductors and prevent electrochemical corrosion, single conductor wires are often tinned to become tinned copper wires. The cable conductor can be divided into compact and non compact type according to the manufacturing process. The compact cable conductor can save materials and reduce costs, but a single conductor is no longer a regular circle. In addition to conductors with small cross section, cable conductors are usually stranded structures, which can ensure high flexibility and strong flexibility of cables, and are not prone to insulation damage and plastic deformation. From the appearance of the cable, the stranded conductor can be divided into sector, circle, hollow circle, etc. According to the number of cable conductor cores, cables can also be divided into single core cables and multi-core cables. The insulation quality and level of power cables play a decisive role in the structure of the service life of cables. Marine power cables are classified according to the commonly used insulation types. Cable filling and shielding layer The gap between the multi-core cable cores must be filled with materials (such as non hygroscopic materials), which can not only separate the filler from the sheath, but also extrude the filler and the sheath into a whole, and can also wrap the non hygroscopic tape between the core and the sheath. In addition, there is a shielding layer inside the cable to optimize the electric field distribution inside the cable. The cable conductor is usually twisted by multiple wires. There must be a gap between the conductor and the insulation layer, and the local electric field will be concentrated. Setting an internal shielding layer between the conductor and the insulation layer can effectively solve this problem and prevent partial discharge between the core and the insulation layer. The external shielding layer is set between the insulation layer and the sheath to make the potential between the sheath and the shielding layer equal, and the contact between the insulation layer and the shielding layer is good, so as to avoid partial discharge. Cable sheath The protective layer of power cable is generally divided into two types: non-metallic and metal armored protective layer. The protective layer of the cable is mainly used to prevent mechanical damage to the cable, and to avoid the impact of environmental factors such as oil, salt and moisture on the cable insulation layer.

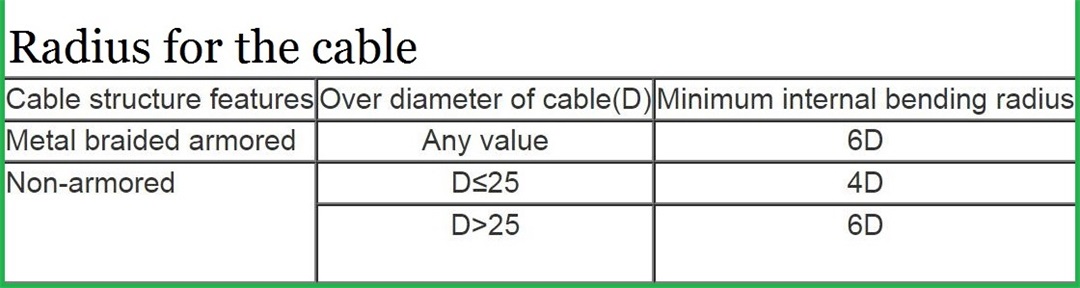

Cable structure: Conductor: Conductor conforms to VDE02956 Insulation: special TPE insulation, black and white insulation core, digital identification number Central reinforcement: nylon reinforcement core or Kevlar bulletproof wire reinforced Inner protection: inner sheath special TPU, PUR reinforcement Parts: Braided reinforcement layer Outer sheath: Outer sheath imported special TPU, PUR polyurethane Product features: The running speed can reach 180 m/min. The inner and outer sheaths are braided with non-woven fabric to prevent friction, and the overall bearing braid prevents cable twisting. Technical requirements: 1. The allowable bending radius of the cable: the minimum is 6 times the outer diameter of the cable for unarmored cables, and 12 times the outer diameter of the cable for armored cables; 2. The product has excellent electrical and physical properties and is light in weight , Good flexibility, low smoke, halogen-free, flame retardant, low toxicity and other characteristics; 3, Rated voltage is 0.6/1KV.

Cable structure: Conductor: Conductor conforms to VDE02956 Insulation: special TPE insulation, black and white insulation core, digital identification number Central reinforcement: nylon reinforcement core or Kevlar bulletproof wire reinforced Inner protection: inner sheath special TPU, PUR reinforcement Parts: Braided reinforcement layer Outer sheath: Outer sheath imported special TPU, PUR polyurethane Product features: The running speed can reach 180 m/min. The inner and outer sheaths are braided with non-woven fabric to prevent friction, and the overall bearing braid prevents cable twisting. Technical requirements: 1. The allowable bending radius of the cable: the minimum is 6 times the outer diameter of the cable for unarmored cables, and 12 times the outer diameter of the cable for armored cables; 2. The product has excellent electrical and physical properties and is light in weight , Good flexibility, low smoke, halogen-free, flame retardant, low toxicity and other characteristics; 3, Rated voltage is 0.6/1KV.