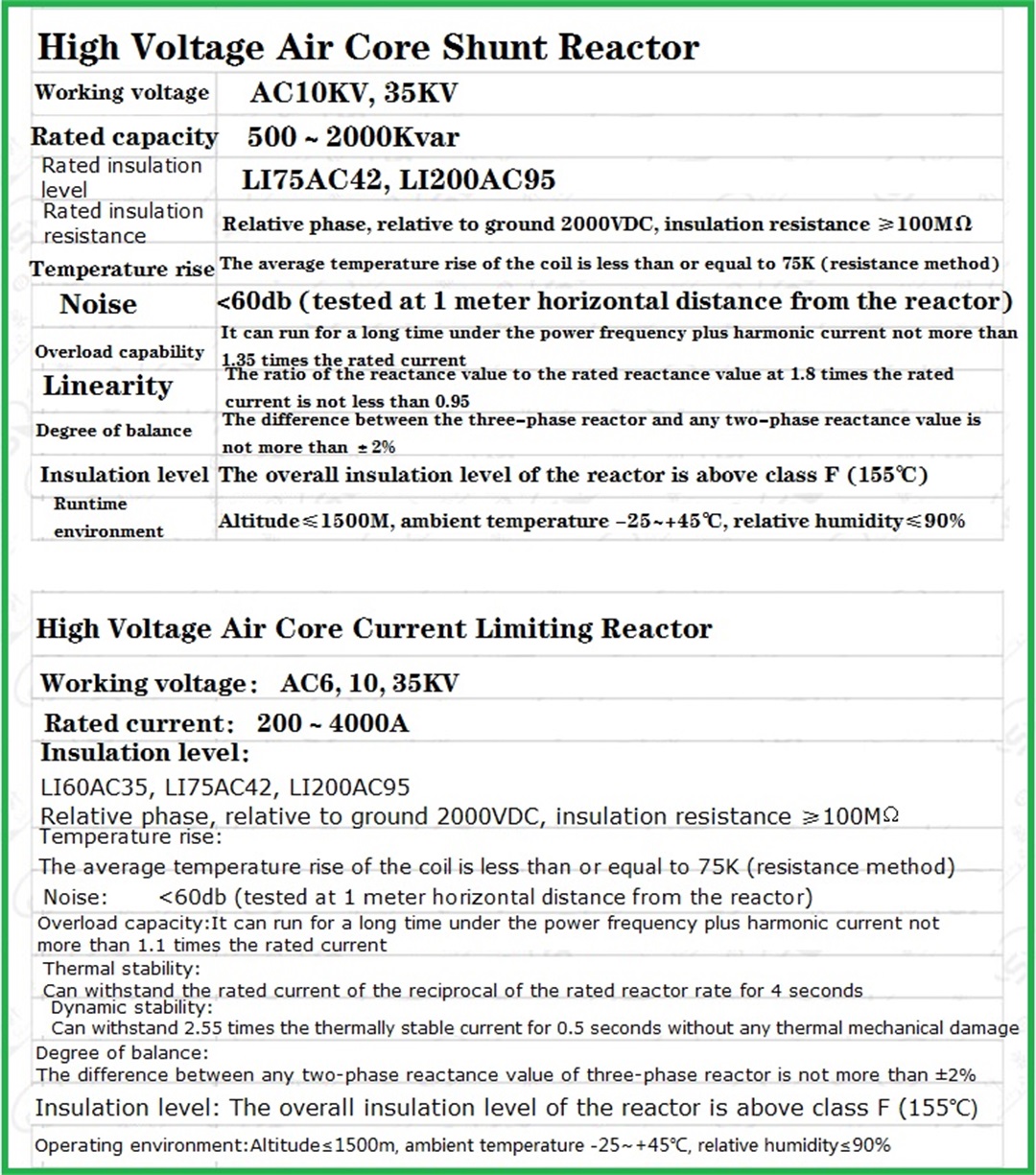

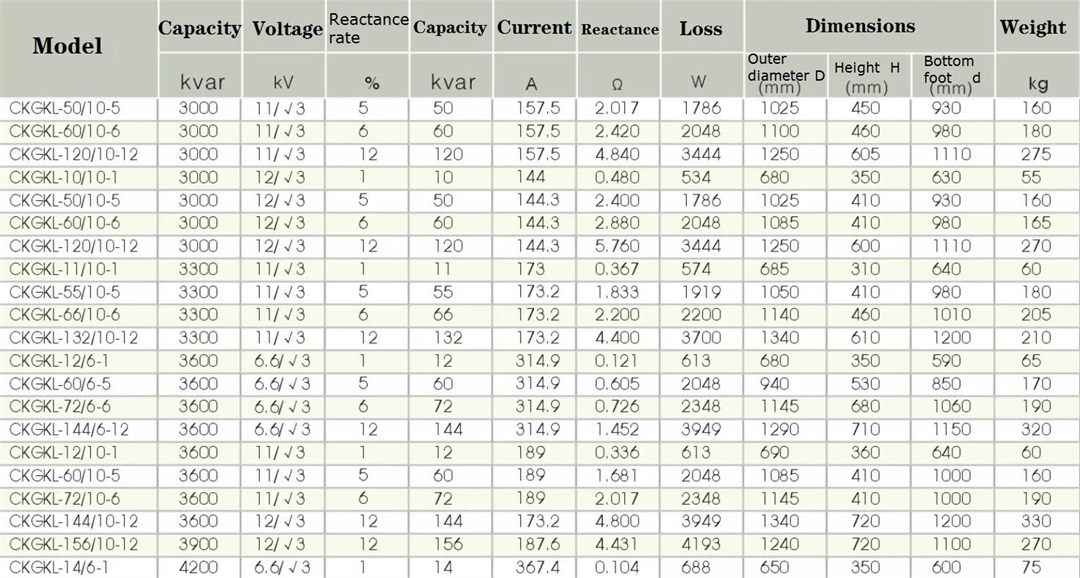

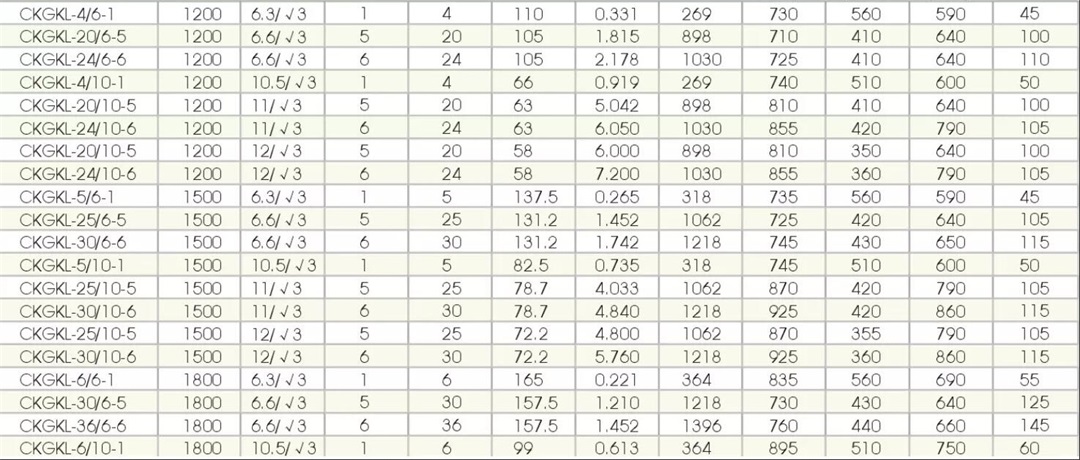

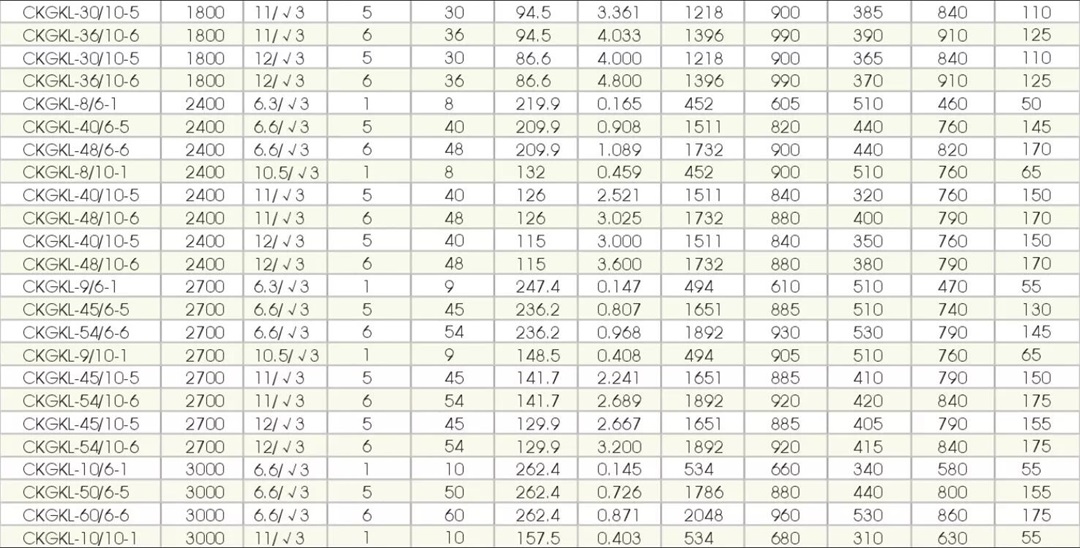

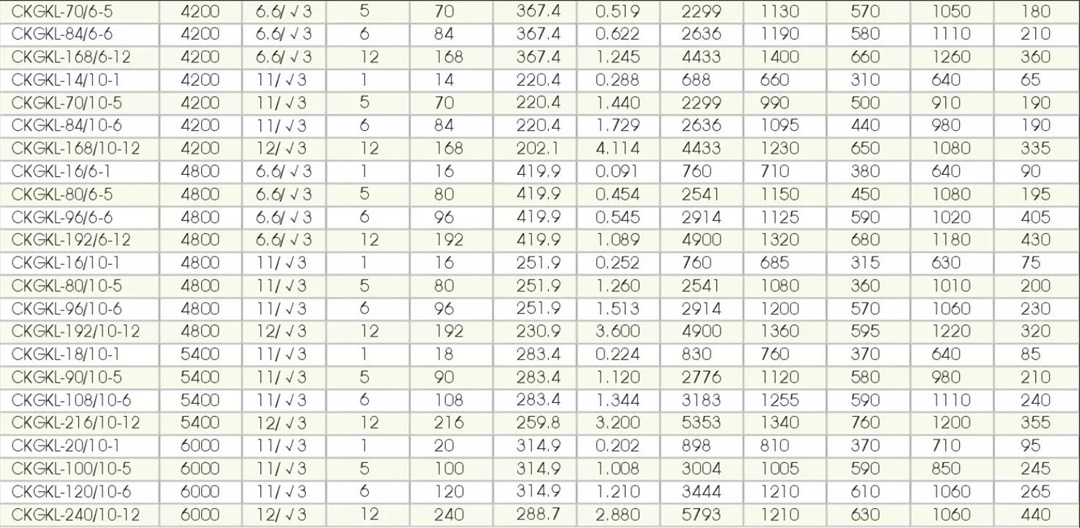

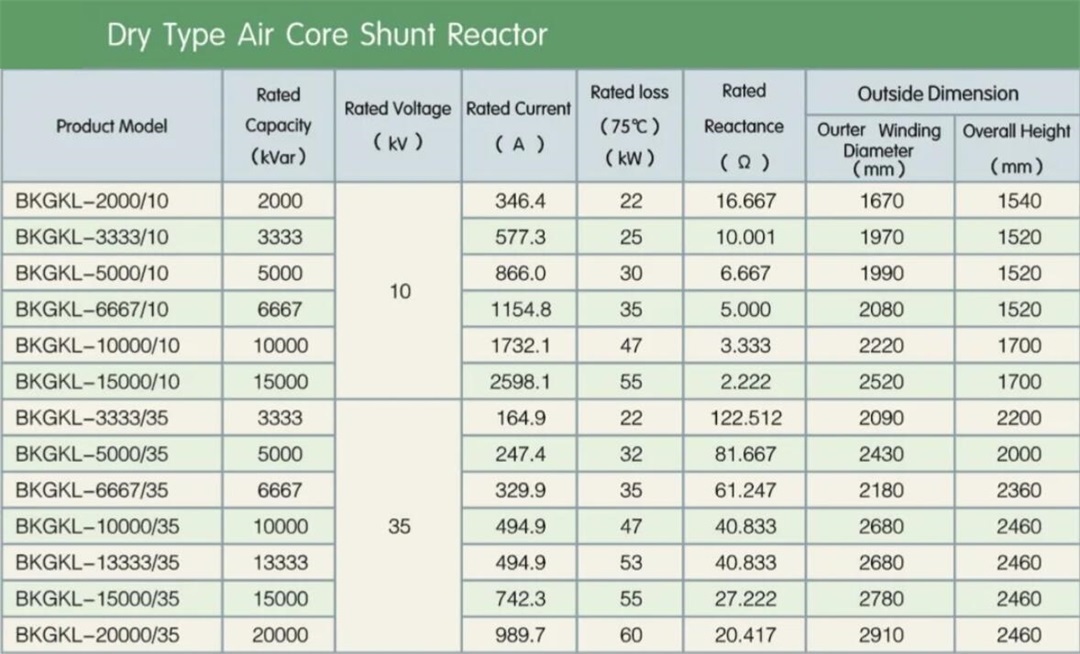

1. Rated working voltage: AC 6kV 10kV 35kV 2. Type of reactance rate: 4% 6% 8% 10% 12% 3. Rated insulation level: AC35LI75 4. The temperature rise of each part of the reactor: the temperature rise of the coil is less than or equal to 75K 5. Reactor noise: less than 65dB (tested at 1 meter horizontal distance from the reactor) 7. Overload capacity: The reactor can run for a long time under the power frequency plus harmonic current not more than 1.2 times the rated current. 8. Reactance value balance: the difference between any two-phase reactance values of the three-phase reactor is not more than ±2% 9. Temperature resistance and insulation grade: the overall insulation level of the reactor is above grade F (155℃) 10. Operating environment: use altitude ≤ 1500 meters, ambient temperature -25 ℃ ~ + 45 ℃, relative humidity ≤ 90% 11. Product implementation standard: GB1094.6-2011 JB/T 5346-2013

1. Rated working voltage: AC 6kV 10kV 35kV 2. Type of reactance rate: 4% 6% 8% 10% 12% 3. Rated insulation level: AC35LI75 4. The temperature rise of each part of the reactor: the temperature rise of the coil is less than or equal to 75K 5. Reactor noise: less than 65dB (tested at 1 meter horizontal distance from the reactor) 7. Overload capacity: The reactor can run for a long time under the power frequency plus harmonic current not more than 1.2 times the rated current. 8. Reactance value balance: the difference between any two-phase reactance values of the three-phase reactor is not more than ±2% 9. Temperature resistance and insulation grade: the overall insulation level of the reactor is above grade F (155℃) 10. Operating environment: use altitude ≤ 1500 meters, ambient temperature -25 ℃ ~ + 45 ℃, relative humidity ≤ 90% 11. Product implementation standard: GB1094.6-2011 JB/T 5346-2013

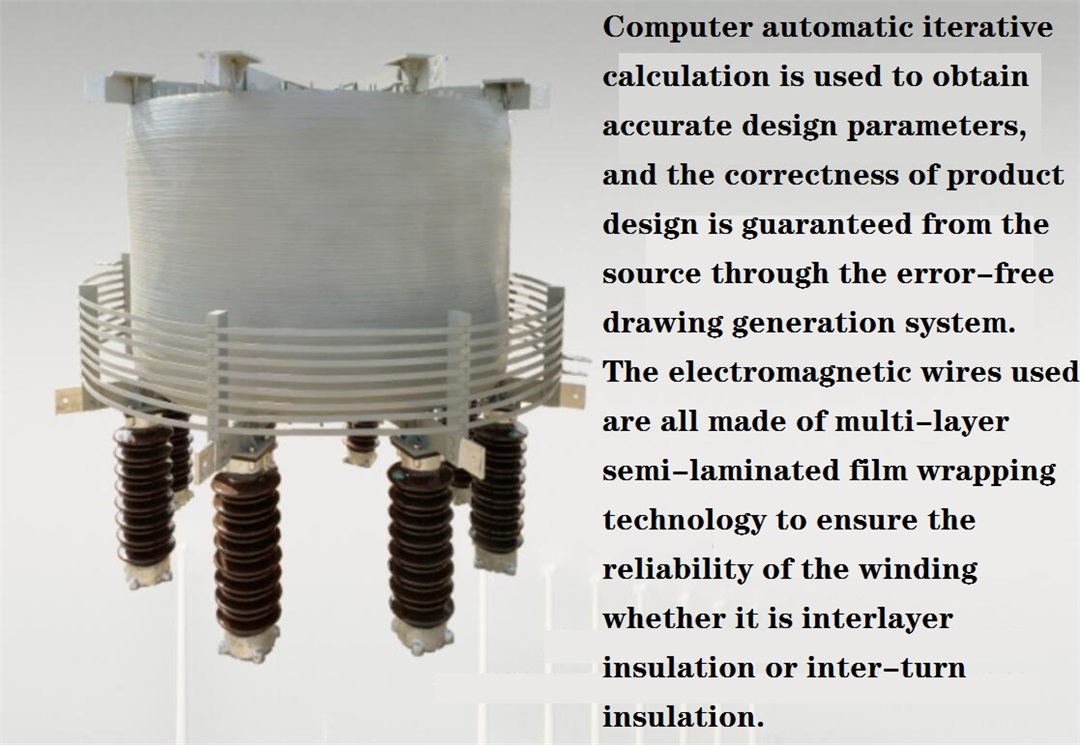

Structural features: 1. Oil-free structure eliminates the shortcomings of oil-immersed reactors such as oil leakage and flammability, and ensures safe operation. There is no iron core, there is no ferromagnetic saturation, and the linearity of the inductance value is good; 2. Applying the computer to optimize the design of the dry-type air-core reactor, it can quickly and accurately design better structural parameters according to the different requirements of users; 3. It adopts a cylindrical structure with multi-layer windings in parallel, and there is a ventilation channel between each package, which has good heat dissipation and low hot spot temperature; 4. The windings are made of small cross-section round wires and multiple parallel windings, which can significantly reduce the eddy current loss and leakage loss; 5. The outside of the winding is tightly wrapped with glass fiber impregnated with epoxy resin, and cured at high temperature, so that it has good integrity, high mechanical strength, and strong ability to withstand short-term current impact; 6. The use of aluminum star connection frame with high mechanical strength, the eddy current loss is small; 7. The entire inner and outer surfaces of the hollow reactor are coated with a special anti-ultraviolet anti-aging protective layer, which has strong adhesion and can withstand harsh outdoor weather conditions; 8. The installation method can be three-phase vertical, and can also be character or in-line; outdoor use can greatly reduce infrastructure investment; 9. Safe operation, low noise, no need for frequent maintenance; 10. According to user requirements, its inductance can be adjusted, and the adjustment range can reach 5% or more. Applicable environment: 1. The altitude does not exceed 2000m; 2. Ambient temperature -25~+45(℃), relative humidity not exceeding 90%; 3. The waveform of the power supply voltage is similar to a sine wave; 4. There is no harmful gas around, no flammable and explosive materials; 5. The surrounding environment should have good ventilation conditions. If it is installed in the cabinet, ventilation equipment should be installed.

Structural features: 1. Oil-free structure eliminates the shortcomings of oil-immersed reactors such as oil leakage and flammability, and ensures safe operation. There is no iron core, there is no ferromagnetic saturation, and the linearity of the inductance value is good; 2. Applying the computer to optimize the design of the dry-type air-core reactor, it can quickly and accurately design better structural parameters according to the different requirements of users; 3. It adopts a cylindrical structure with multi-layer windings in parallel, and there is a ventilation channel between each package, which has good heat dissipation and low hot spot temperature; 4. The windings are made of small cross-section round wires and multiple parallel windings, which can significantly reduce the eddy current loss and leakage loss; 5. The outside of the winding is tightly wrapped with glass fiber impregnated with epoxy resin, and cured at high temperature, so that it has good integrity, high mechanical strength, and strong ability to withstand short-term current impact; 6. The use of aluminum star connection frame with high mechanical strength, the eddy current loss is small; 7. The entire inner and outer surfaces of the hollow reactor are coated with a special anti-ultraviolet anti-aging protective layer, which has strong adhesion and can withstand harsh outdoor weather conditions; 8. The installation method can be three-phase vertical, and can also be character or in-line; outdoor use can greatly reduce infrastructure investment; 9. Safe operation, low noise, no need for frequent maintenance; 10. According to user requirements, its inductance can be adjusted, and the adjustment range can reach 5% or more. Applicable environment: 1. The altitude does not exceed 2000m; 2. Ambient temperature -25~+45(℃), relative humidity not exceeding 90%; 3. The waveform of the power supply voltage is similar to a sine wave; 4. There is no harmful gas around, no flammable and explosive materials; 5. The surrounding environment should have good ventilation conditions. If it is installed in the cabinet, ventilation equipment should be installed.

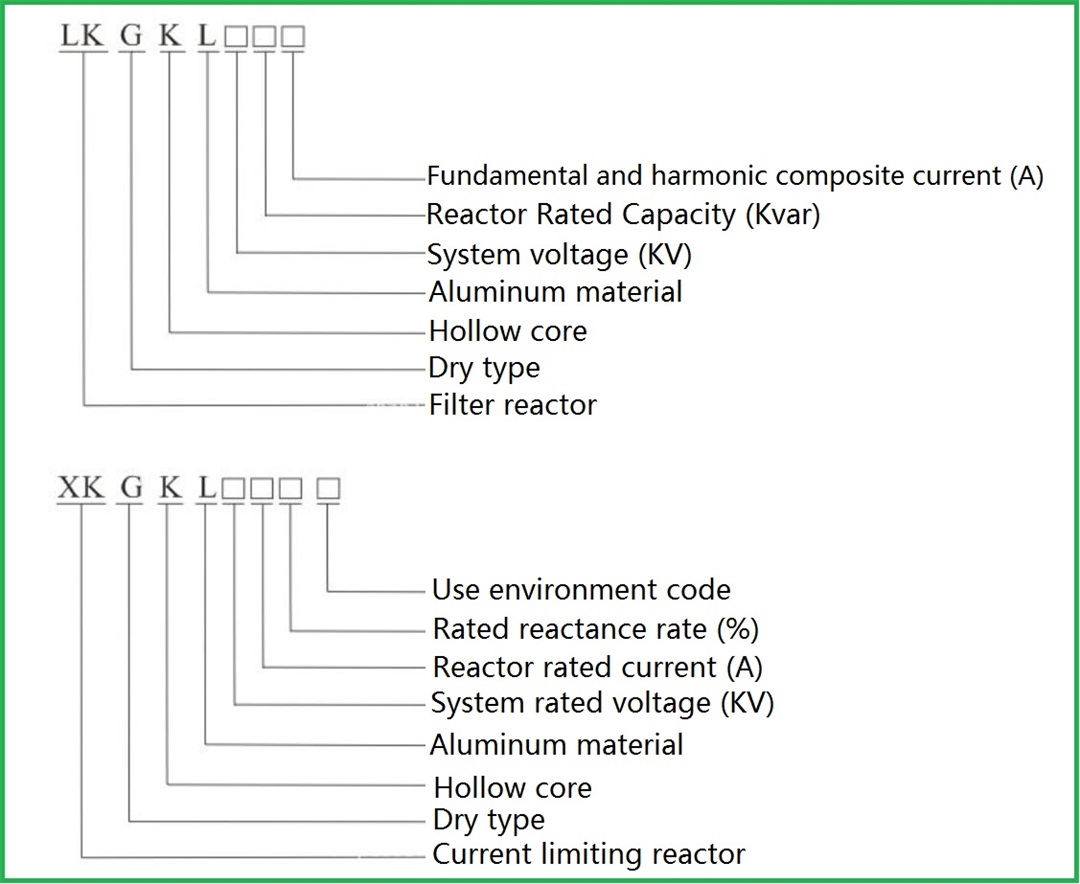

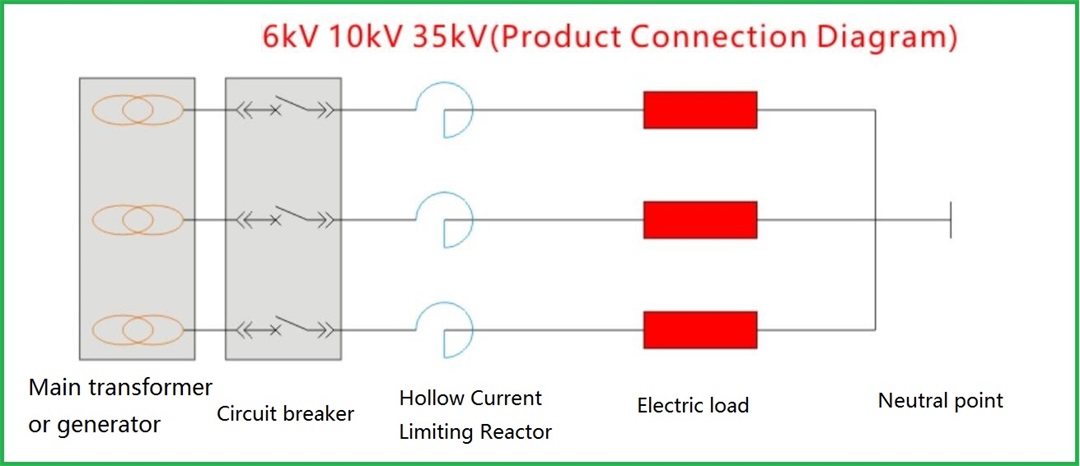

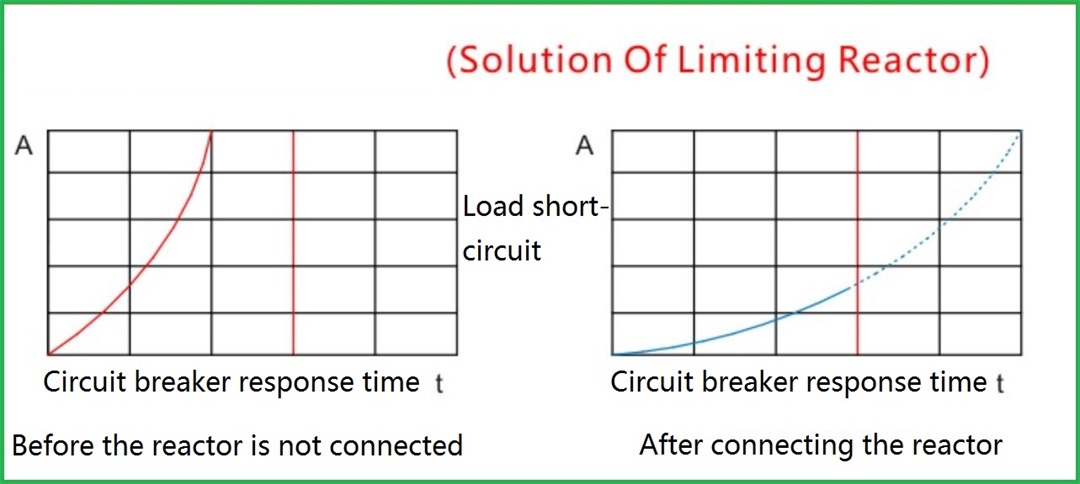

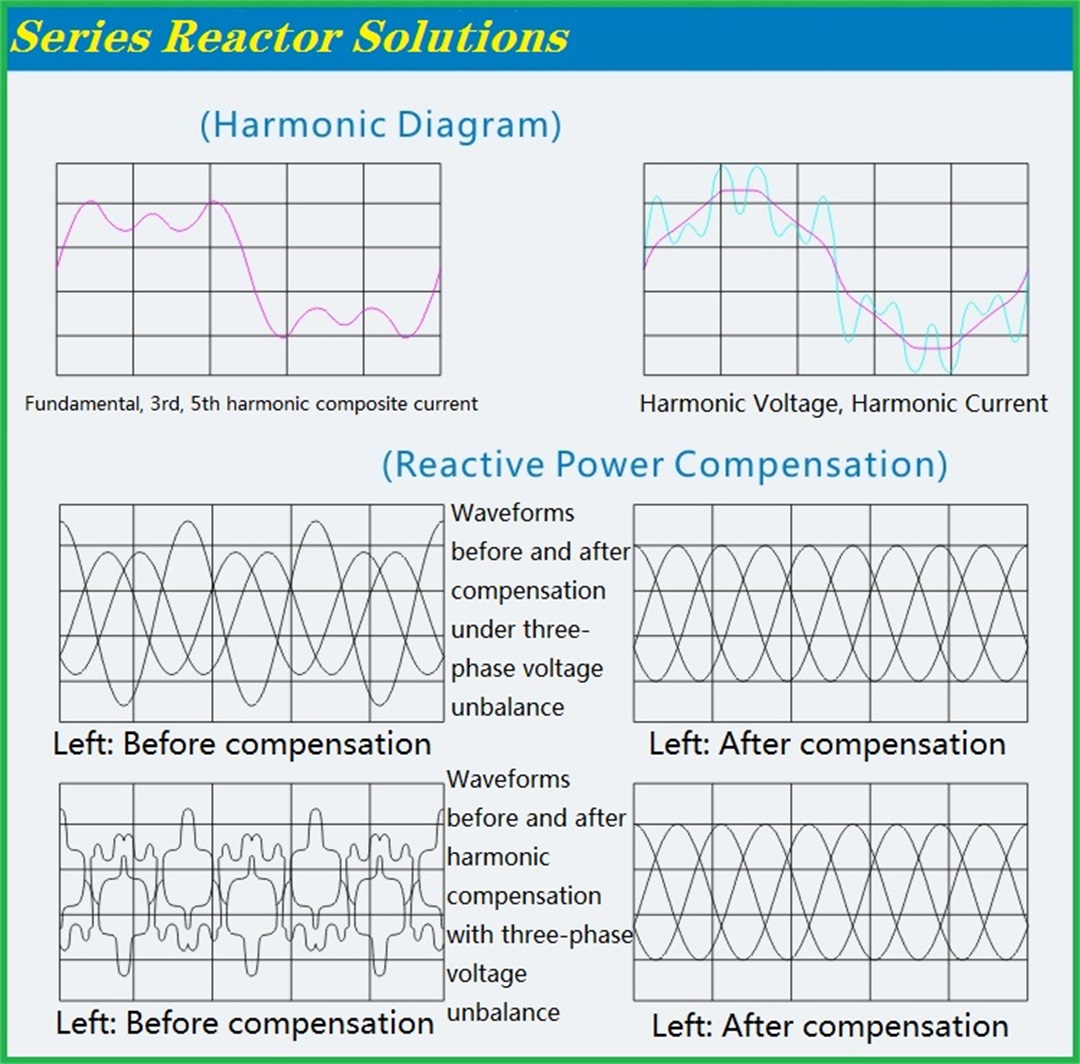

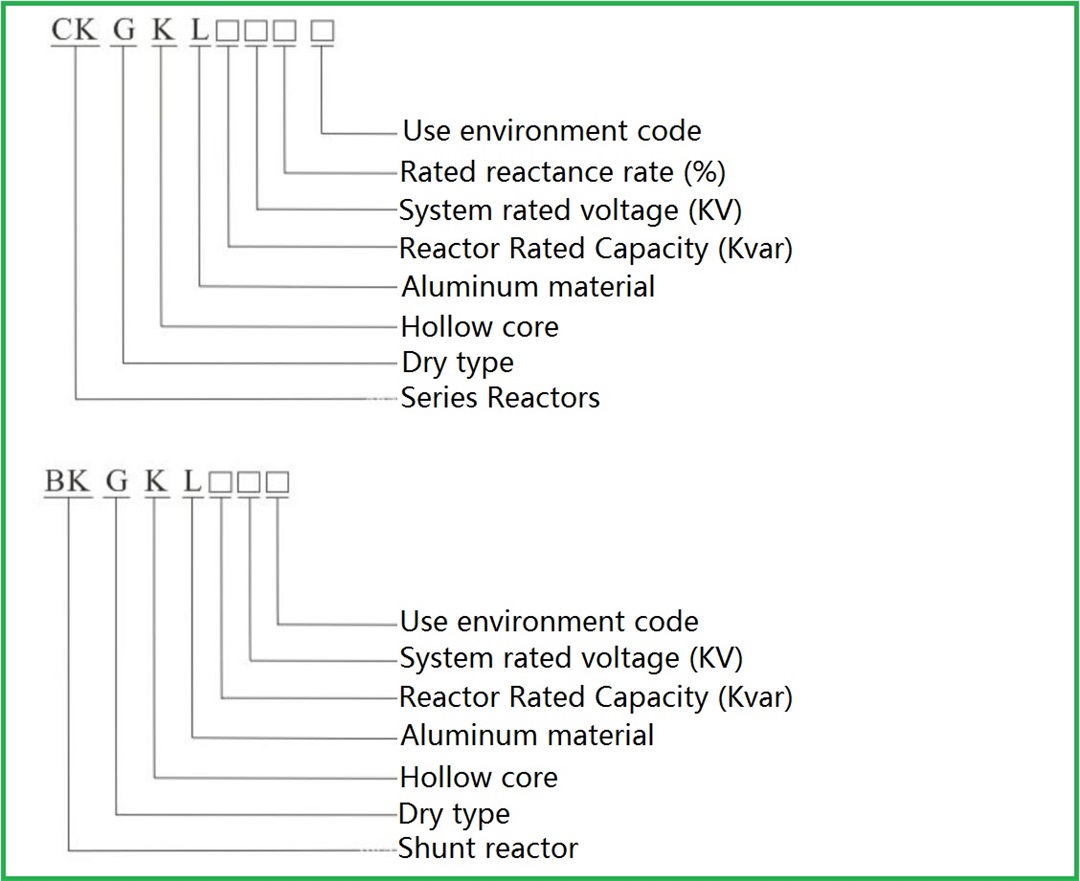

Common types and uses: a. The series reactor is connected in series with the capacitor in the parallel capacitor compensation device to suppress the harmonic current and limit the closing inrush current. b. The current limiting reactor is connected in series with the power system to limit the short-circuit current and limit the short-circuit current within the allowable range when the system fails. c. The shunt reactor is connected in parallel with the power system, and transmits inductive reactive power through the main conversion system to compensate the capacitive current of the transmission line, prevent the voltage of the light-load line terminal from rising, and maintain the voltage stability of the transmission system. d. The filter reactor is used in series with the parallel capacitor bank to form a tuning loop to filter out specific high-order harmonics and ensure the power supply quality of the power grid. Ordering instructions: 1. System rated storage voltage 2. Rated current of reactor 3. Rated reactance rate 4. Rated capacity of reactor 5. Installation method (horizontal or stacked) 6. Use environment (indoor or outdoor) 7. The angle of the lunatic in and out of the line 8. Special requirements are clearly stated Note: The above data are for reference only, and the specific parameters are subject to the factory products.

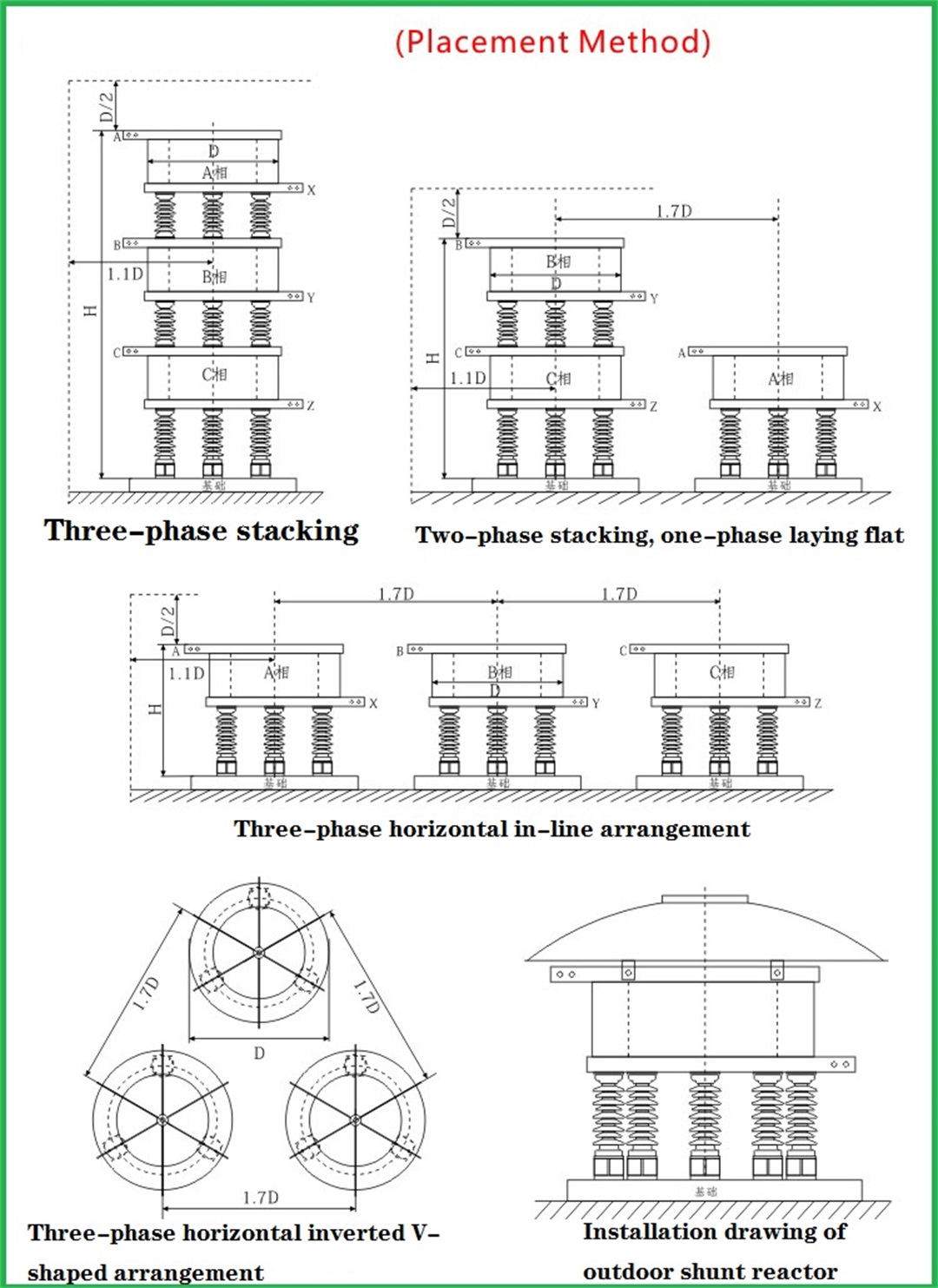

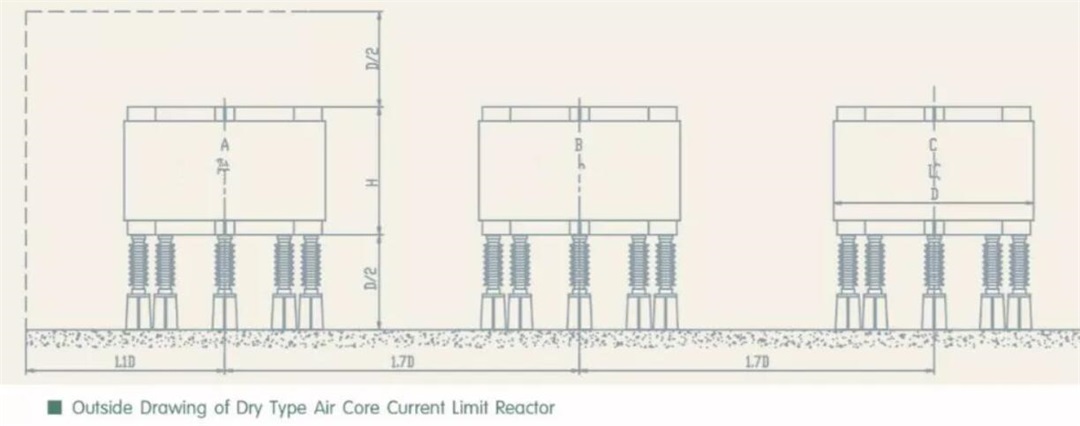

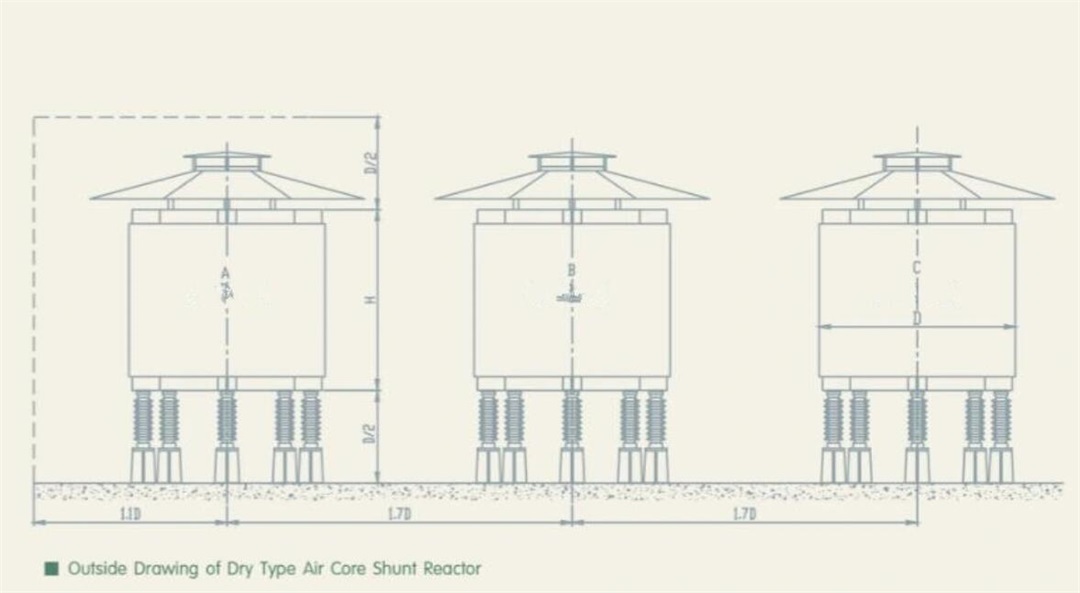

Common types and uses: a. The series reactor is connected in series with the capacitor in the parallel capacitor compensation device to suppress the harmonic current and limit the closing inrush current. b. The current limiting reactor is connected in series with the power system to limit the short-circuit current and limit the short-circuit current within the allowable range when the system fails. c. The shunt reactor is connected in parallel with the power system, and transmits inductive reactive power through the main conversion system to compensate the capacitive current of the transmission line, prevent the voltage of the light-load line terminal from rising, and maintain the voltage stability of the transmission system. d. The filter reactor is used in series with the parallel capacitor bank to form a tuning loop to filter out specific high-order harmonics and ensure the power supply quality of the power grid. Ordering instructions: 1. System rated storage voltage 2. Rated current of reactor 3. Rated reactance rate 4. Rated capacity of reactor 5. Installation method (horizontal or stacked) 6. Use environment (indoor or outdoor) 7. The angle of the lunatic in and out of the line 8. Special requirements are clearly stated Note: The above data are for reference only, and the specific parameters are subject to the factory products. Reactor placement: 1. The high-voltage hollow current-limiting reactor is connected in series with the output end of the secondary circuit of the main transformer or generator. 2. The placement methods of the series high-voltage hollow current-limiting reactors are divided into: three-phase laying, two stacking and one laying, and three-phase stacking. 3. The reactor wiring is not divided into incoming and outgoing lines, any end can be an incoming line, but the three-phase wiring must be consistent. 4. The mounting feet of the reactor are also grounding points. Please ensure reliable grounding during installation. Multiple feet cannot form a loop. 5. The fastening screws of the feet need to be fixed in place to avoid noise due to poor installation. 6. The reactor is a magnetic component and should be installed away from magnetically conductive materials, such as iron fences, iron columns, walls, etc. Installation Precautions: 1. The following installation methods do not consider the non-ferromagnetic space with closed turns and other reactors, 2. There shall be no coarse metal objects within 1.1 D of the center of the reactor body, and no closed loop can be formed (Note: D is the outer diameter of the reactor body). 3. There should be no closed steel bars or metal objects in the reactor installation foundation. 4. The center distance between adjacent two groups (or two sets) of reactors is not less than 1.7 D.

Reactor placement: 1. The high-voltage hollow current-limiting reactor is connected in series with the output end of the secondary circuit of the main transformer or generator. 2. The placement methods of the series high-voltage hollow current-limiting reactors are divided into: three-phase laying, two stacking and one laying, and three-phase stacking. 3. The reactor wiring is not divided into incoming and outgoing lines, any end can be an incoming line, but the three-phase wiring must be consistent. 4. The mounting feet of the reactor are also grounding points. Please ensure reliable grounding during installation. Multiple feet cannot form a loop. 5. The fastening screws of the feet need to be fixed in place to avoid noise due to poor installation. 6. The reactor is a magnetic component and should be installed away from magnetically conductive materials, such as iron fences, iron columns, walls, etc. Installation Precautions: 1. The following installation methods do not consider the non-ferromagnetic space with closed turns and other reactors, 2. There shall be no coarse metal objects within 1.1 D of the center of the reactor body, and no closed loop can be formed (Note: D is the outer diameter of the reactor body). 3. There should be no closed steel bars or metal objects in the reactor installation foundation. 4. The center distance between adjacent two groups (or two sets) of reactors is not less than 1.7 D.