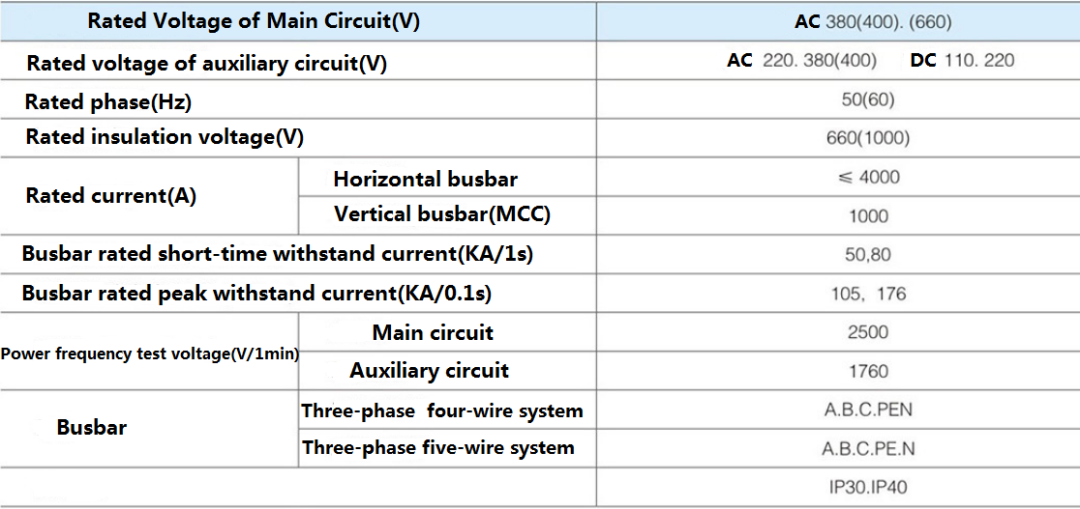

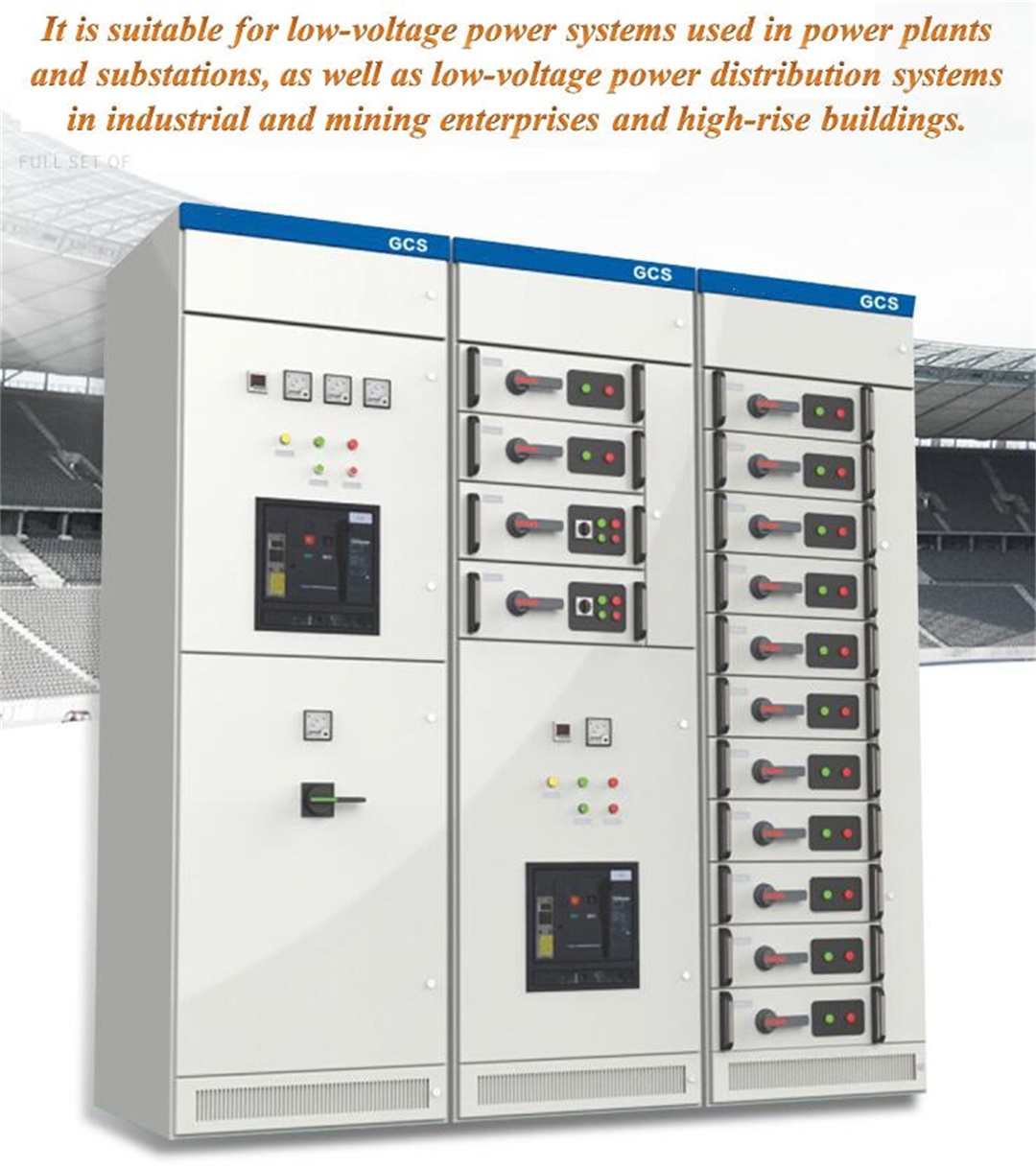

1.Increase the heat capacity of the adapter, and greatly reduce the additional temperature rise caused by the temperature rise of the adapter to the connector, cable head, and spacer plate. 2.The separation between functional units and compartments is clear and reliable, and the failure of one unit does not affect the work of other units, so that the failure is limited to a minimum. 3.The horizontal arrangement of the busbar makes the device have good dynamic and thermal stability, and can withstand the impact of 80/176kA short-circuit current. 4.The number of circuits in a single MCC cabinet is as many as 22, and the needs of large single-unit power generation, petrochemical systems and other industries for automated electric door (machine) groups are fully considered. 5.The connection between the device and the external cable is completed in the cable compartment, and the cables can be entered and exited up and down. The zero sequence current transformer is placed in the cable compartment, making installation and maintenance easy. 6.The drawer unit has a sufficient number of secondary plug-ins (32 pairs for 1 unit and above, 20 pairs for 1/2 unit). It can meet the requirements of the number of connection points of the computer interface and the automatic control loop.

1.Increase the heat capacity of the adapter, and greatly reduce the additional temperature rise caused by the temperature rise of the adapter to the connector, cable head, and spacer plate. 2.The separation between functional units and compartments is clear and reliable, and the failure of one unit does not affect the work of other units, so that the failure is limited to a minimum. 3.The horizontal arrangement of the busbar makes the device have good dynamic and thermal stability, and can withstand the impact of 80/176kA short-circuit current. 4.The number of circuits in a single MCC cabinet is as many as 22, and the needs of large single-unit power generation, petrochemical systems and other industries for automated electric door (machine) groups are fully considered. 5.The connection between the device and the external cable is completed in the cable compartment, and the cables can be entered and exited up and down. The zero sequence current transformer is placed in the cable compartment, making installation and maintenance easy. 6.The drawer unit has a sufficient number of secondary plug-ins (32 pairs for 1 unit and above, 20 pairs for 1/2 unit). It can meet the requirements of the number of connection points of the computer interface and the automatic control loop. 1. Ambient air temperature: -5~+40 and the average temperature should not exceed +35 in 24h. 2. Install and use indoors. Altitude above sea level for operation site should not exceed 2000M. 3. Relative humidity should not exceed 50% at max temperature +40. Higher relative humidity is allowed at lower temperature. Ex. 90% at +20. But in view of the temperature change, it is possible that moderate dews will produce casually. 4. Installation gradient not exceed 5. 5. Install in the places without fierce vibration and shock and the sites insufficient to erode the electrical components. 6. Any specific requirement, consult with manufactory.

1. Ambient air temperature: -5~+40 and the average temperature should not exceed +35 in 24h. 2. Install and use indoors. Altitude above sea level for operation site should not exceed 2000M. 3. Relative humidity should not exceed 50% at max temperature +40. Higher relative humidity is allowed at lower temperature. Ex. 90% at +20. But in view of the temperature change, it is possible that moderate dews will produce casually. 4. Installation gradient not exceed 5. 5. Install in the places without fierce vibration and shock and the sites insufficient to erode the electrical components. 6. Any specific requirement, consult with manufactory.