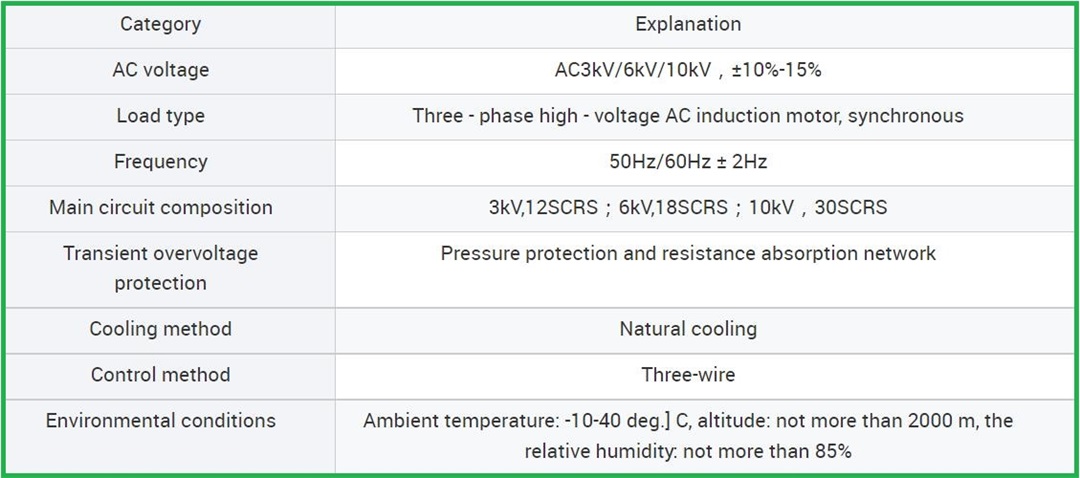

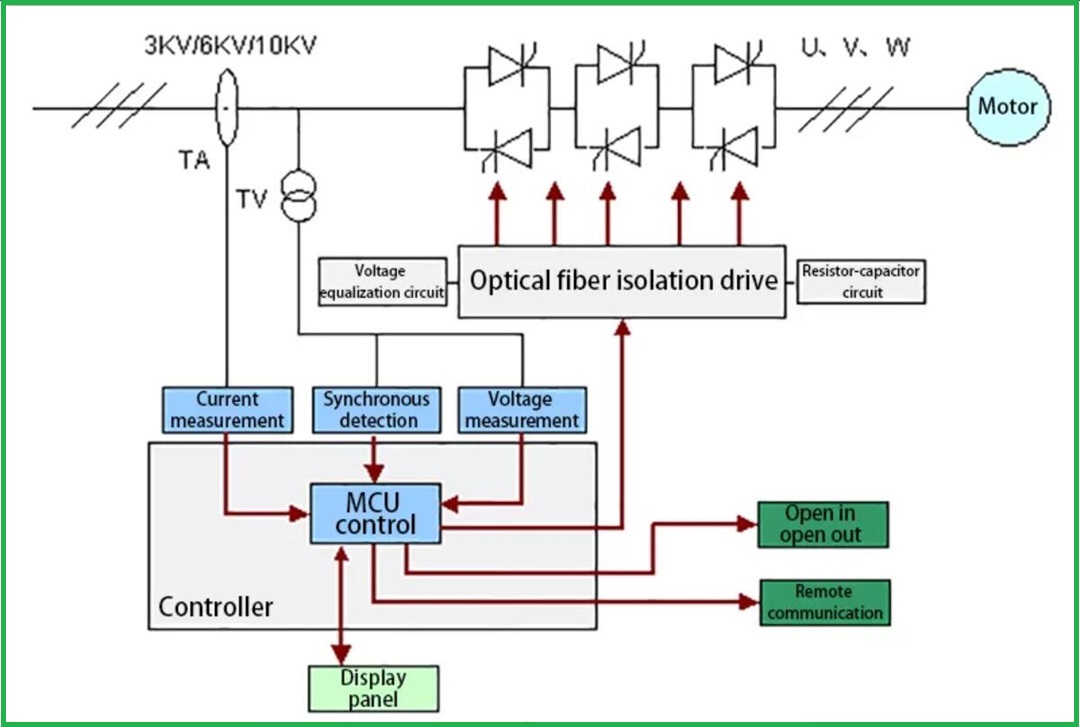

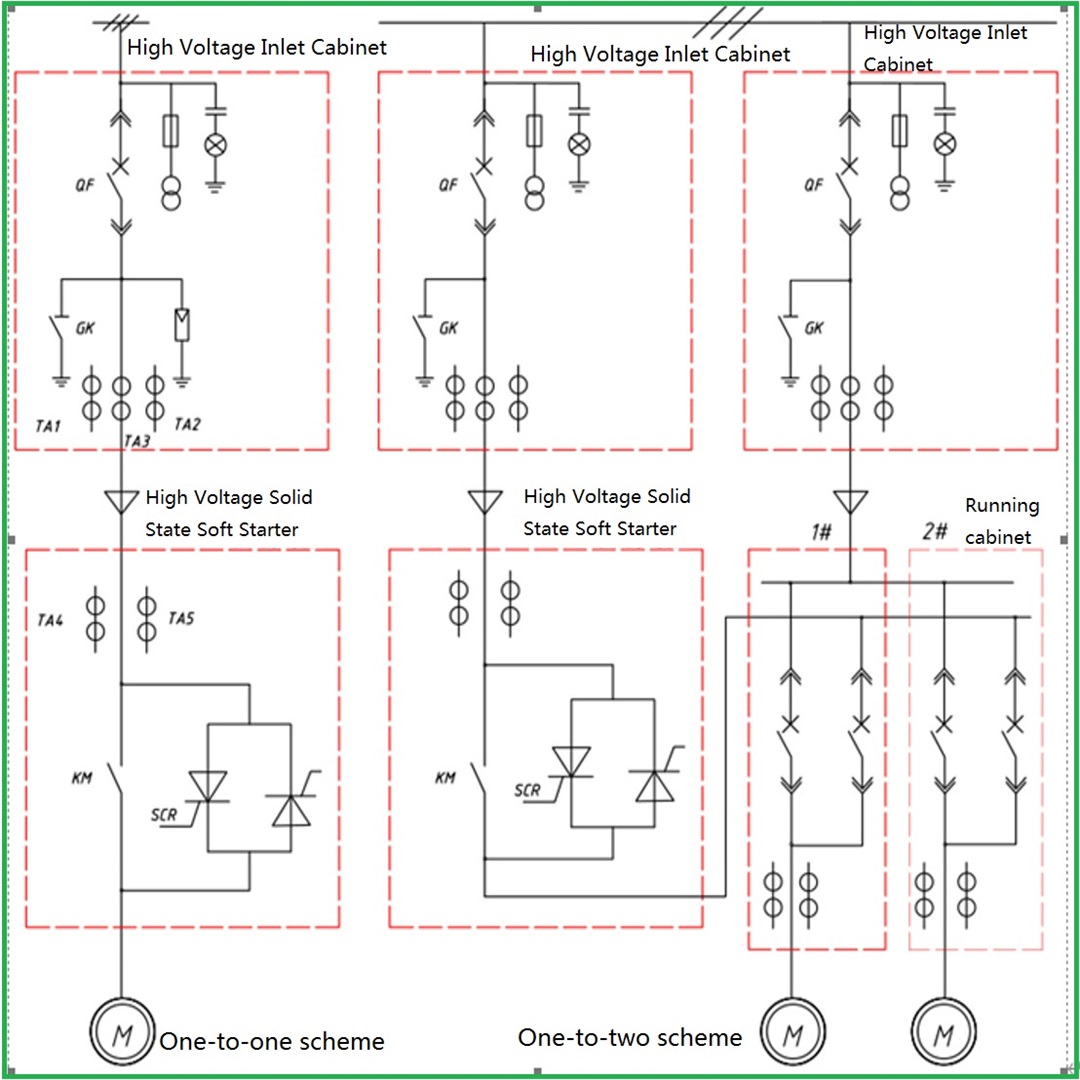

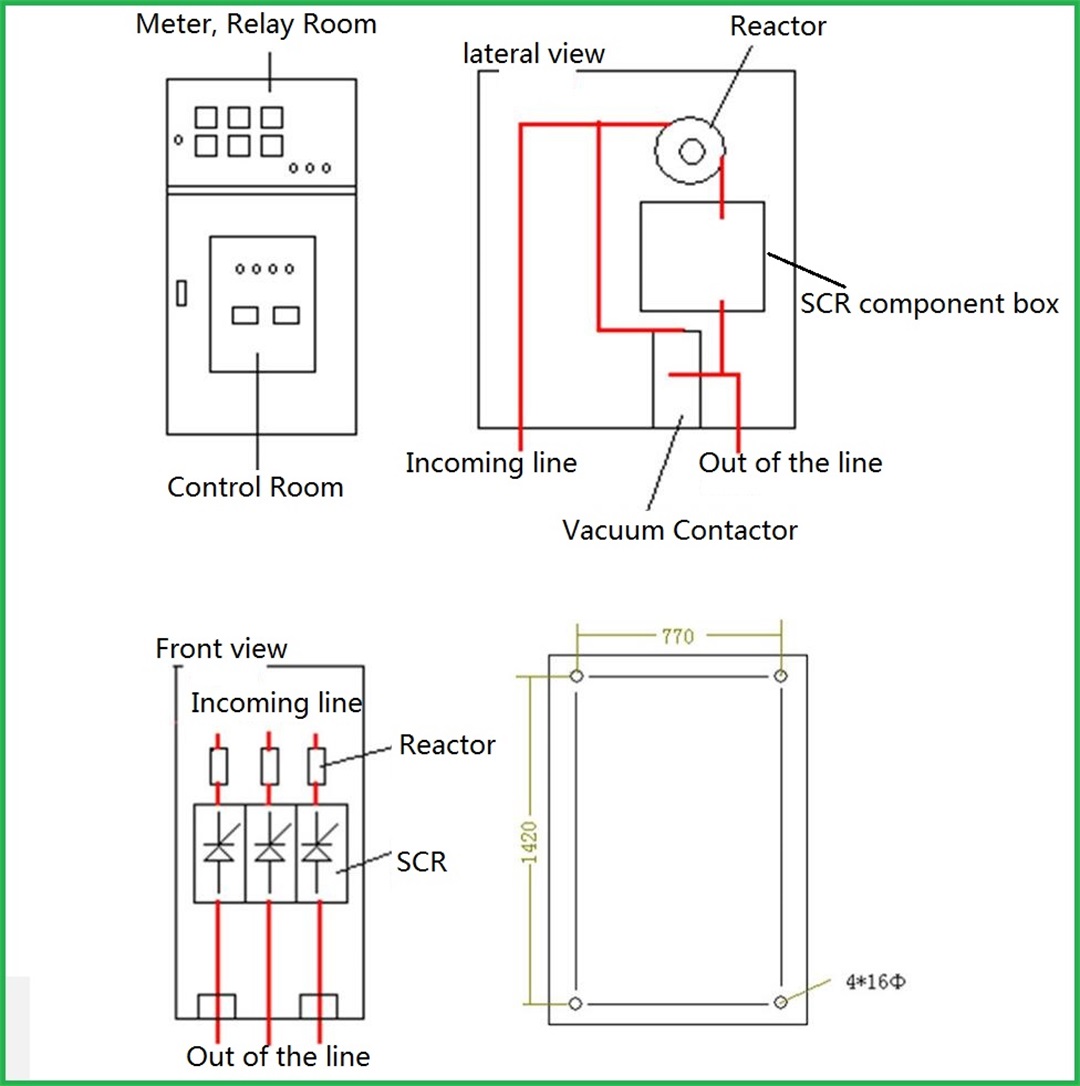

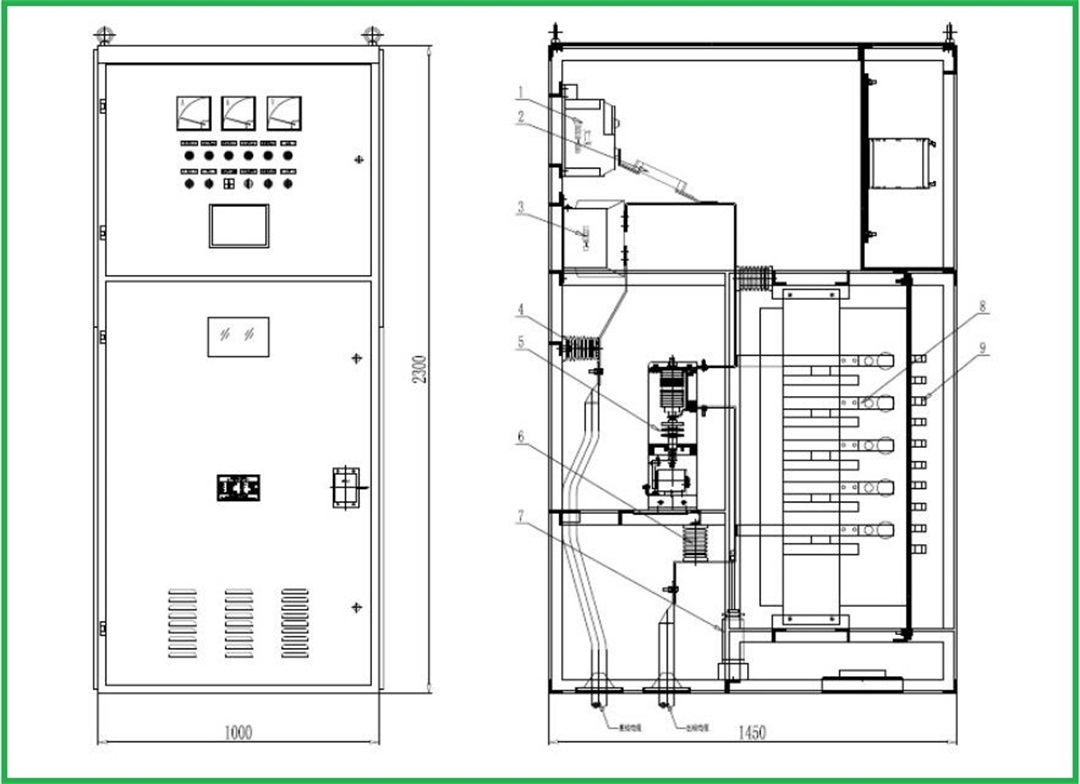

1. Smooth start and soft stop avoid the surge problem and water hammer effect of traditional starting equipment; 2. A variety of starting modes and a wide range of current and voltage settings can be adapted to various load occasions and improve the process. 3. Improve the reliable protection function and more effectively protect the safety of the motor and related equipment. 4. Reducing the starting current of the motor can avoid voltage drop and voltage dip in the power supply. Reduce power distribution capacity and avoid investment in capacity expansion. 5. Reduce the starting stress and prolong the service life of the motor and related equipment. Save maintenance costs and save a lot of money. Soft start device configuration: It is divided into two structures: the superior motor outlet cabinet, the cable from the motor starting cabinet to the soft starting cabinet, and the cable from the soft starting cabinet to the motor. Integrated high-voltage solid-state soft-start cabinet, switch cabinet and soft-start are integrated into one switch cabinet, which is small in size and easy to install, and can be installed together with other switch cabinets. Normal working conditions: (1) The upper limit of the ambient temperature is not more than 50°C (the average temperature in 24 hours is not more than 35°C), and the lower limit is not lower than -15°C; (2) The relative humidity does not exceed 95%; the altitude does not exceed 1000m, and the capacity should be reduced when it exceeds 1000m; (3) It should be placed indoors, without severe vibration and shock, and without fire and explosion hazards; (4) Conductive dust and corrosive gas are not allowed.

1. Smooth start and soft stop avoid the surge problem and water hammer effect of traditional starting equipment; 2. A variety of starting modes and a wide range of current and voltage settings can be adapted to various load occasions and improve the process. 3. Improve the reliable protection function and more effectively protect the safety of the motor and related equipment. 4. Reducing the starting current of the motor can avoid voltage drop and voltage dip in the power supply. Reduce power distribution capacity and avoid investment in capacity expansion. 5. Reduce the starting stress and prolong the service life of the motor and related equipment. Save maintenance costs and save a lot of money. Soft start device configuration: It is divided into two structures: the superior motor outlet cabinet, the cable from the motor starting cabinet to the soft starting cabinet, and the cable from the soft starting cabinet to the motor. Integrated high-voltage solid-state soft-start cabinet, switch cabinet and soft-start are integrated into one switch cabinet, which is small in size and easy to install, and can be installed together with other switch cabinets. Normal working conditions: (1) The upper limit of the ambient temperature is not more than 50°C (the average temperature in 24 hours is not more than 35°C), and the lower limit is not lower than -15°C; (2) The relative humidity does not exceed 95%; the altitude does not exceed 1000m, and the capacity should be reduced when it exceeds 1000m; (3) It should be placed indoors, without severe vibration and shock, and without fire and explosion hazards; (4) Conductive dust and corrosive gas are not allowed.