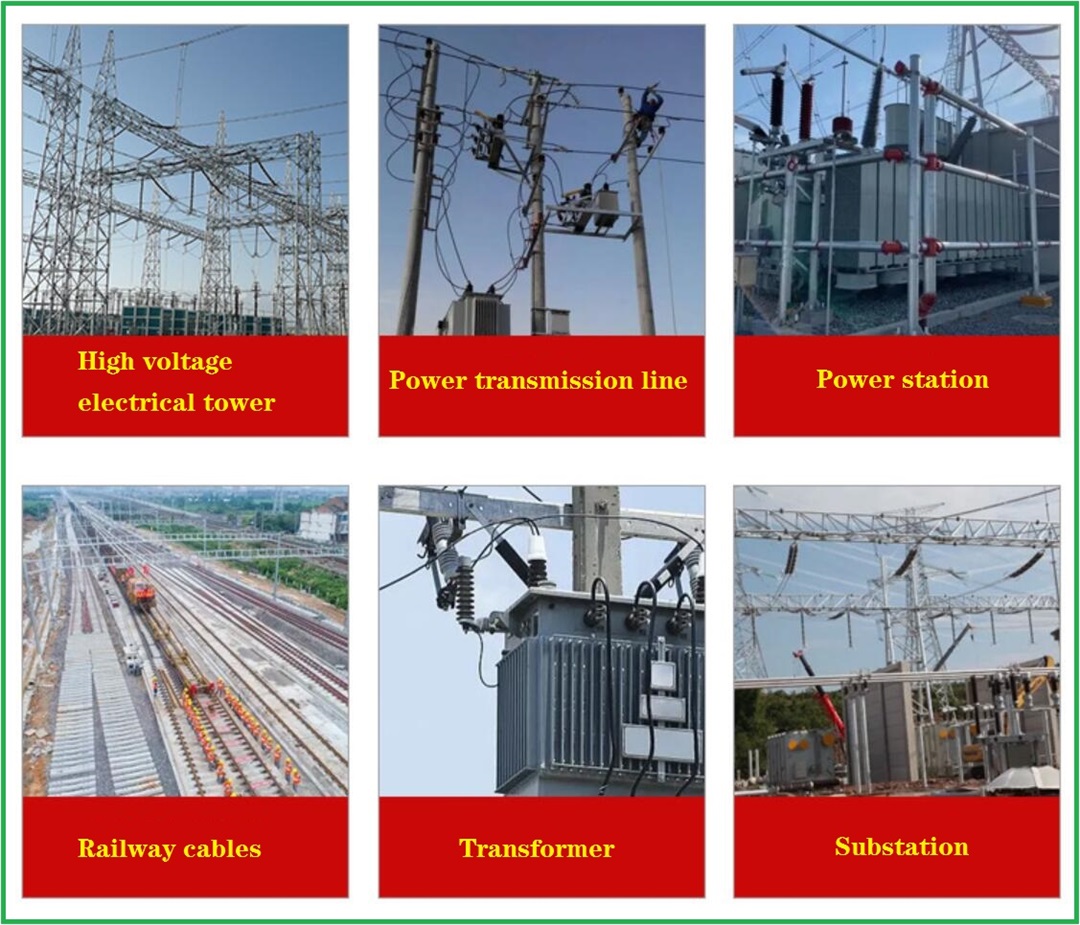

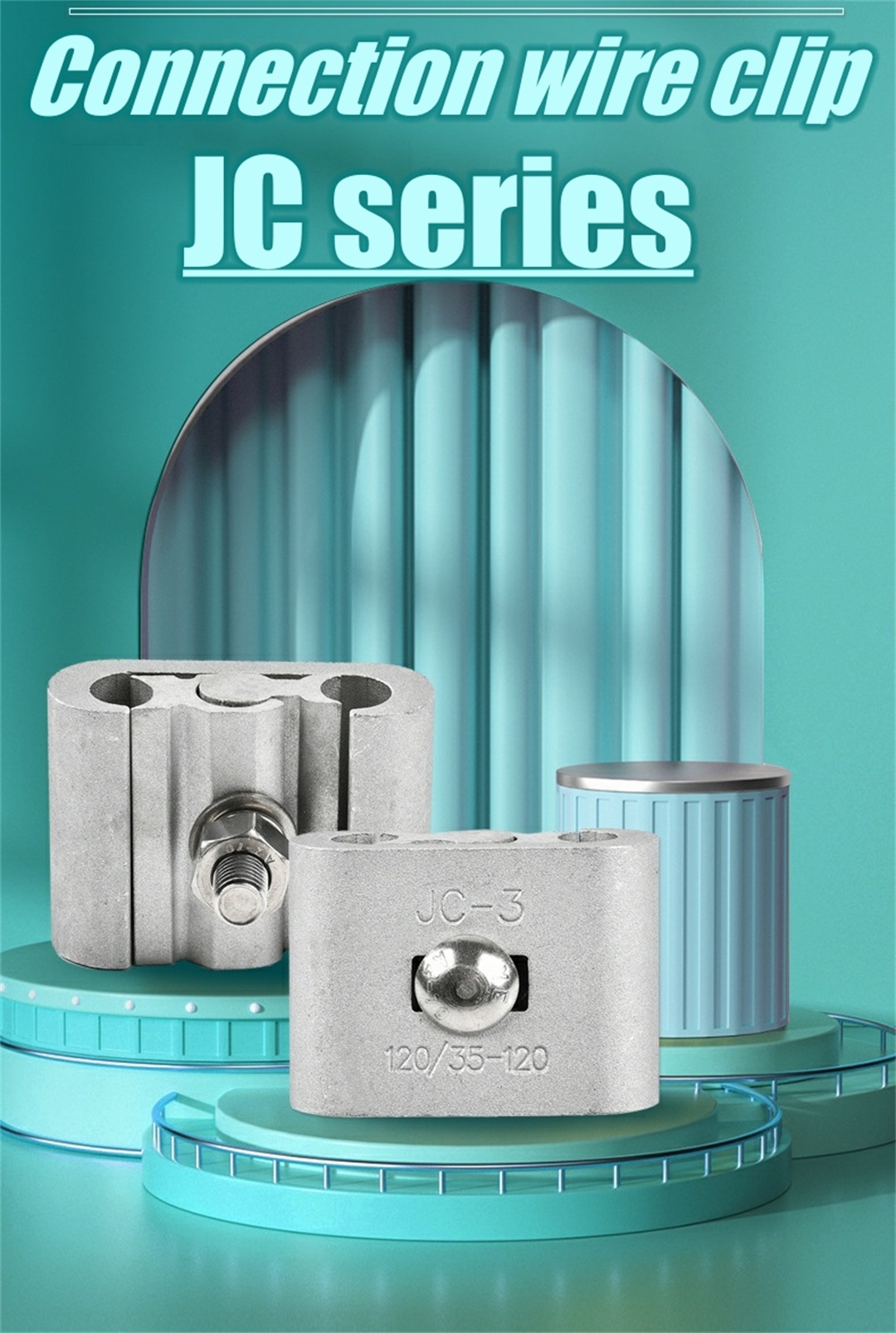

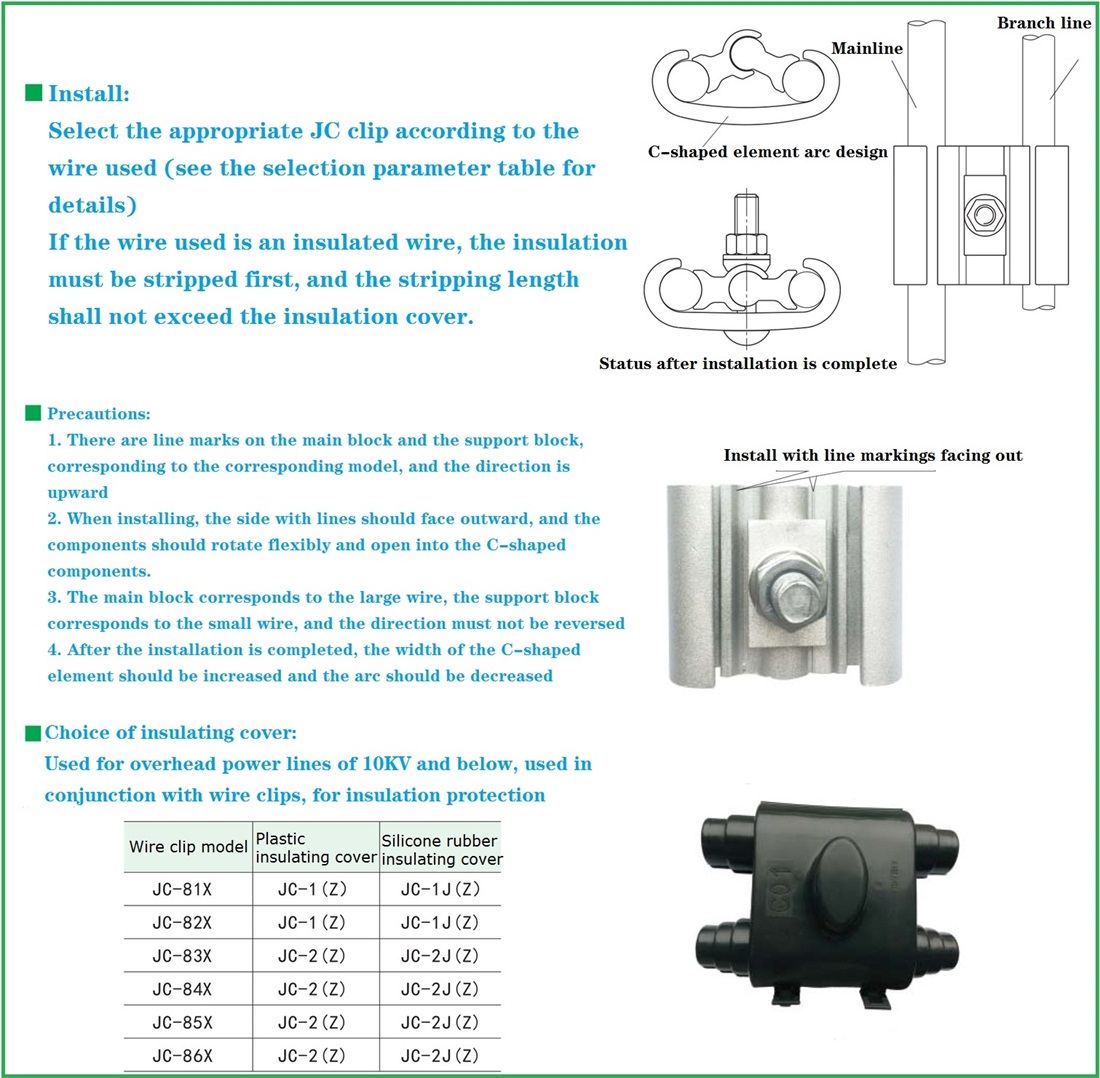

Features: 1. Contact performance: large contact area, constant clamping force, and DC resistance ratio between 0.85-0.9. 2. Overload capacity: the overload capacity reaches more than 2 times of the rated current. 3, firm performance: high-strength material. The stainless steel bolts are fastened, the connection is reliable, and it will never fall off. 4. Thermal cycle performance: The thermal cycle performance is good, always running below the DC resistance ratio of 1. 5. Installation: easy to install and disassemble, suitable for high-altitude work. 6. Energy-saving performance: Made of high-strength special aluminum alloy, no electromagnetic loss, anti-corrosion, anti-oxidation. Application range: C-type clips can be used in electrical lightning protection grounding projects that require firm connection and non-detachable connection, such as power grounding grids, lightning protection grounding grids, etc. The UL standard lists: Clamping type clamps can be used as the connection between grounding stranded wires, grounding round solid core conductors, copper grounding rods, etc. directly buried in the grounding system, and can also be used for the connection of power cables. In particular, the connection of conductors in concrete or soil has various forms and is convenient for construction and installation. Wedge-type articulated C-type clamp is suitable for T-connection and parallel-line connection in non-tension positions such as steel-cored aluminum stranded wire, overhead insulated wire, aluminum stranded wire, aluminum-clad steel wire, and copper wire on power transmission and distribution lines. Flow connection and jumper connection are non-load-bearing connection fittings. Such as: aluminum-aluminum, copper-copper connection, copper-aluminum transition. The installation does not need to use aluminum wrapping tape, and the operation is simple and convenient.

Features: 1. Contact performance: large contact area, constant clamping force, and DC resistance ratio between 0.85-0.9. 2. Overload capacity: the overload capacity reaches more than 2 times of the rated current. 3, firm performance: high-strength material. The stainless steel bolts are fastened, the connection is reliable, and it will never fall off. 4. Thermal cycle performance: The thermal cycle performance is good, always running below the DC resistance ratio of 1. 5. Installation: easy to install and disassemble, suitable for high-altitude work. 6. Energy-saving performance: Made of high-strength special aluminum alloy, no electromagnetic loss, anti-corrosion, anti-oxidation. Application range: C-type clips can be used in electrical lightning protection grounding projects that require firm connection and non-detachable connection, such as power grounding grids, lightning protection grounding grids, etc. The UL standard lists: Clamping type clamps can be used as the connection between grounding stranded wires, grounding round solid core conductors, copper grounding rods, etc. directly buried in the grounding system, and can also be used for the connection of power cables. In particular, the connection of conductors in concrete or soil has various forms and is convenient for construction and installation. Wedge-type articulated C-type clamp is suitable for T-connection and parallel-line connection in non-tension positions such as steel-cored aluminum stranded wire, overhead insulated wire, aluminum stranded wire, aluminum-clad steel wire, and copper wire on power transmission and distribution lines. Flow connection and jumper connection are non-load-bearing connection fittings. Such as: aluminum-aluminum, copper-copper connection, copper-aluminum transition. The installation does not need to use aluminum wrapping tape, and the operation is simple and convenient.