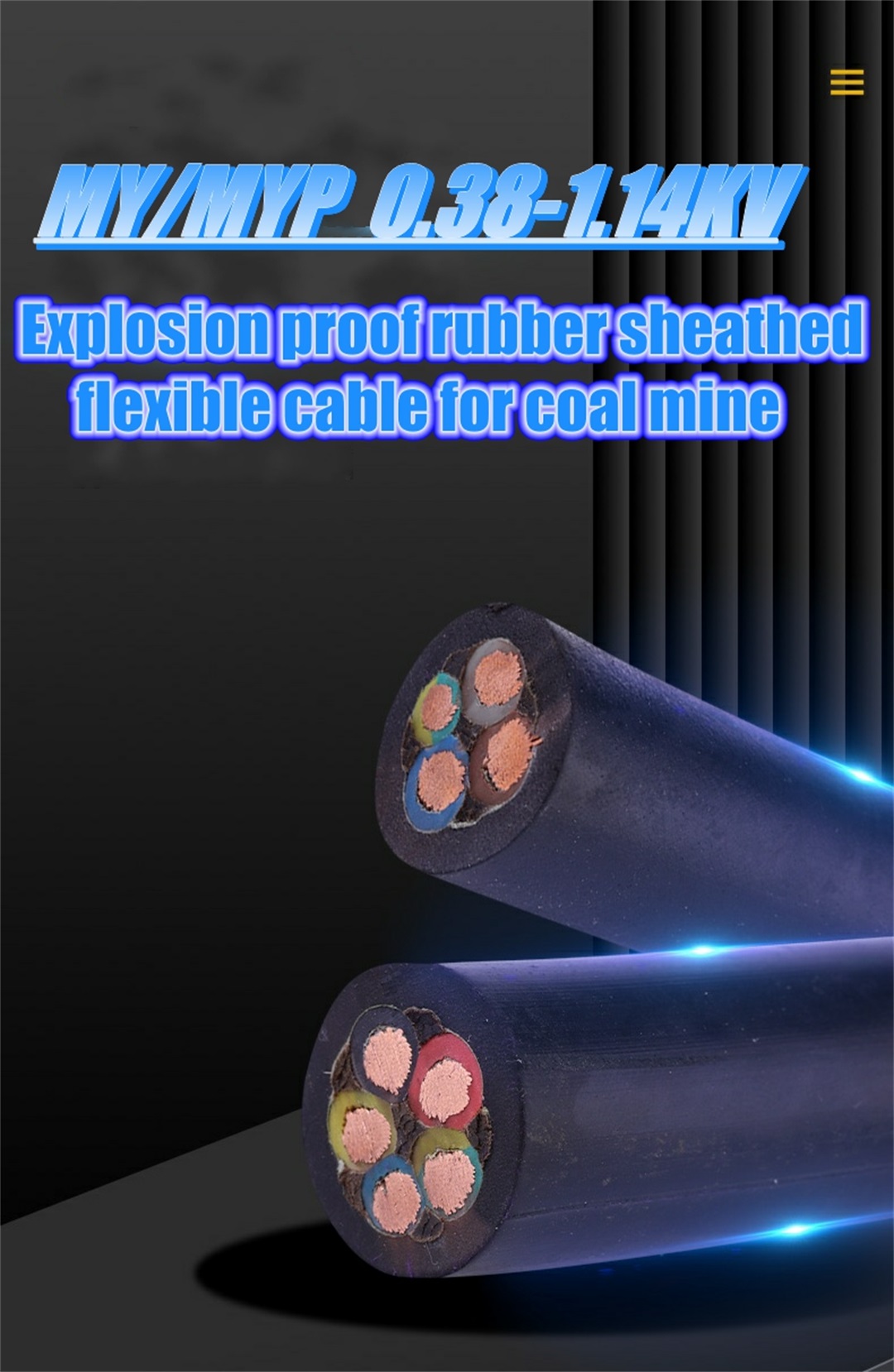

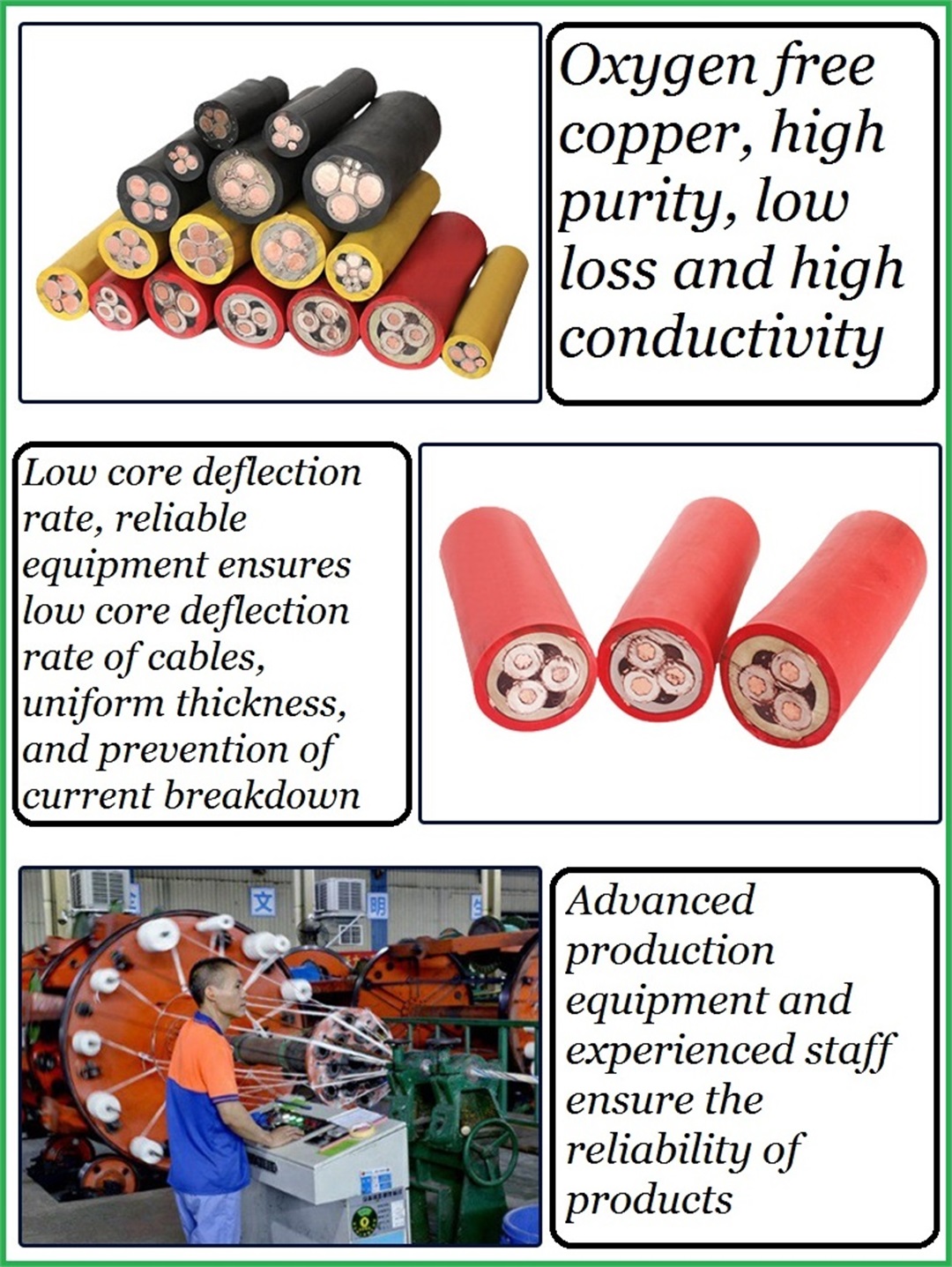

Structural characteristics of rubber sheathed cable for mining: 1: The flexibility of conductor core shall be based on electric drill cable and excavator cable; The following measures shall be taken for conductor structure: 1. Softer copper single wire with fine diameter shall be used, bundled and twisted at small pitch. The bending torsion of the whole cable is also affected by the insulation and sheath structures, so it cannot be considered that the thinner the monofilament is, the smaller the pitch is, the better. 2. The flexibility can be improved by using the same direction stranding and multiple stranding. 3. In order to facilitate the relative sliding of wires in the insulating layer and facilitate the installation and maintenance. The monofilament of electric drill cable and cable conductor of small section excavator shall be tinned, and the cable of large section excavator shall be insulated with paper tape outside the conductor. 2: The insulation layer shall have sufficient electrical insulation performance 1. Use rubber with rubber content no less than 35% 2. The insulation thickness is thicker than that of general rubber sheathed cable 3. Rubber with good electrical property and good rubber extrusion process (such as continuous rubber extrusion and vulcanization production line) 3: MCP cable product introduction MCP shearer shield cable outer diameter dimension layer The semi conductive rubber shall be used as the layer, and its transition resistance shall meet the standard requirements to ensure the reliable action of the relay protection system in the event of an accident. 4: Cushion core The AC breakdown strength has a great relationship with the voltage rise speed. The cable breakdown caused by continuous voltage rise within a few minutes is called instantaneous breakdown. There is basically no thermal factor, and it belongs to the type of electrical breakdown. Therefore, wires and cables are generally not subject to such tests. The other is to step up the voltage step by step, starting from a lower voltage (such as 0.5~2 times of the working voltage), and maintaining sufficient working time to enable the cable to fully generate electricity and heat in this voltage level. Then rise to another voltage level. Rise step by step until breakdown. The rising voltage of each stage increases step by step according to the percentage of initial pressurization. This test reflects the factors of thermal breakdown. The test results are of good reference value. It is often used when researching product characteristics. 7: The cable shall be compact and compact in structure, and each element shall have relative sliding property. This product is a series of rubber sheathed flexible cables for mining. Applicable to: mobile coal mining unit and other equipment with rated voltage of 0.66/1.14KV and below are used to connect power lines. MY-0.38/0.66 Mobile rubber sheathed flexible cable for coal mine with rated voltage of 0.38/0.66KV Power connection of various underground mobile mining equipment MYE-0.38/0.66 Mobile elastomer flexible cable for coal mine with rated voltage of 0.38/0.66KV Power connection of various underground mobile mining equipment MYP-0.38/0.66 Mobile shielded rubber sheathed flexible cable for coal mine with rated voltage of 0.38/0.66KV Power connection of various underground mobile coal mining equipment MYPE-0.38/0.66 Mobile Shielded Elastomer Flexible Cable for Coal Mine with Rated Voltage of 0.38/0.66KV Power Connection of Various Underground Mobile Mining Equipment MYP-0.66/1.14 Mobile shielded rubber sheathed flexible cable for coal mine with rated voltage of 0.66/1.44KV Power connection of various underground mobile coal mining equipment Operating conditions: Rated voltage Uo/U is 0.38/0.66 and 0.66/1.14KV Long term working temperature of cable conductor is 65 ℃ The Z small bending radius of the cable is 6 times of the cable diamete

Matters needing attention: Common cable faults Common faults in cable lines include mechanical damage, insulation damage, insulation damp, insulation aging and deterioration, overvoltage, and cable overheating faults. When the above fault occurs in the line, the power supply of the faulty cable should be cut off, the fault point should be found, the fault should be checked and analyzed, and then repaired and tested. Safety requirements for buried cables 1. When the cables cross each other, the high-voltage cables should be under the low-voltage cables. If one of the cables is protected by pipes within 1m before and after the intersection or separated by partitions, the minimum allowable distance is 0.15m. 2. When the cable is close to or crossed with the heat pipe, if there are thermal insulation measures, the minimum distance between parallel and cross is 0.5m and 0.15m respectively. 3. When the cable crosses the railway or road, it should be protected by a pipe, and the protection pipe should extend beyond 2m from the track or road surface. 4. The distance between the cable and the foundation of the building should be able to ensure that the cable is buried outside the building's water; when the cable is introduced into the building, it should be protected by a pipe, and the protection pipe should also extend beyond the building's water. 5. The distance between the cables directly buried in the ground and the grounding of the general grounding device should be 0.15~0.5m; the buried depth of the cables directly buried in the ground should generally not be less than 0.7m, and should be buried under the frozen soil layer.

Matters needing attention: Common cable faults Common faults in cable lines include mechanical damage, insulation damage, insulation damp, insulation aging and deterioration, overvoltage, and cable overheating faults. When the above fault occurs in the line, the power supply of the faulty cable should be cut off, the fault point should be found, the fault should be checked and analyzed, and then repaired and tested. Safety requirements for buried cables 1. When the cables cross each other, the high-voltage cables should be under the low-voltage cables. If one of the cables is protected by pipes within 1m before and after the intersection or separated by partitions, the minimum allowable distance is 0.15m. 2. When the cable is close to or crossed with the heat pipe, if there are thermal insulation measures, the minimum distance between parallel and cross is 0.5m and 0.15m respectively. 3. When the cable crosses the railway or road, it should be protected by a pipe, and the protection pipe should extend beyond 2m from the track or road surface. 4. The distance between the cable and the foundation of the building should be able to ensure that the cable is buried outside the building's water; when the cable is introduced into the building, it should be protected by a pipe, and the protection pipe should also extend beyond the building's water. 5. The distance between the cables directly buried in the ground and the grounding of the general grounding device should be 0.15~0.5m; the buried depth of the cables directly buried in the ground should generally not be less than 0.7m, and should be buried under the frozen soil layer.