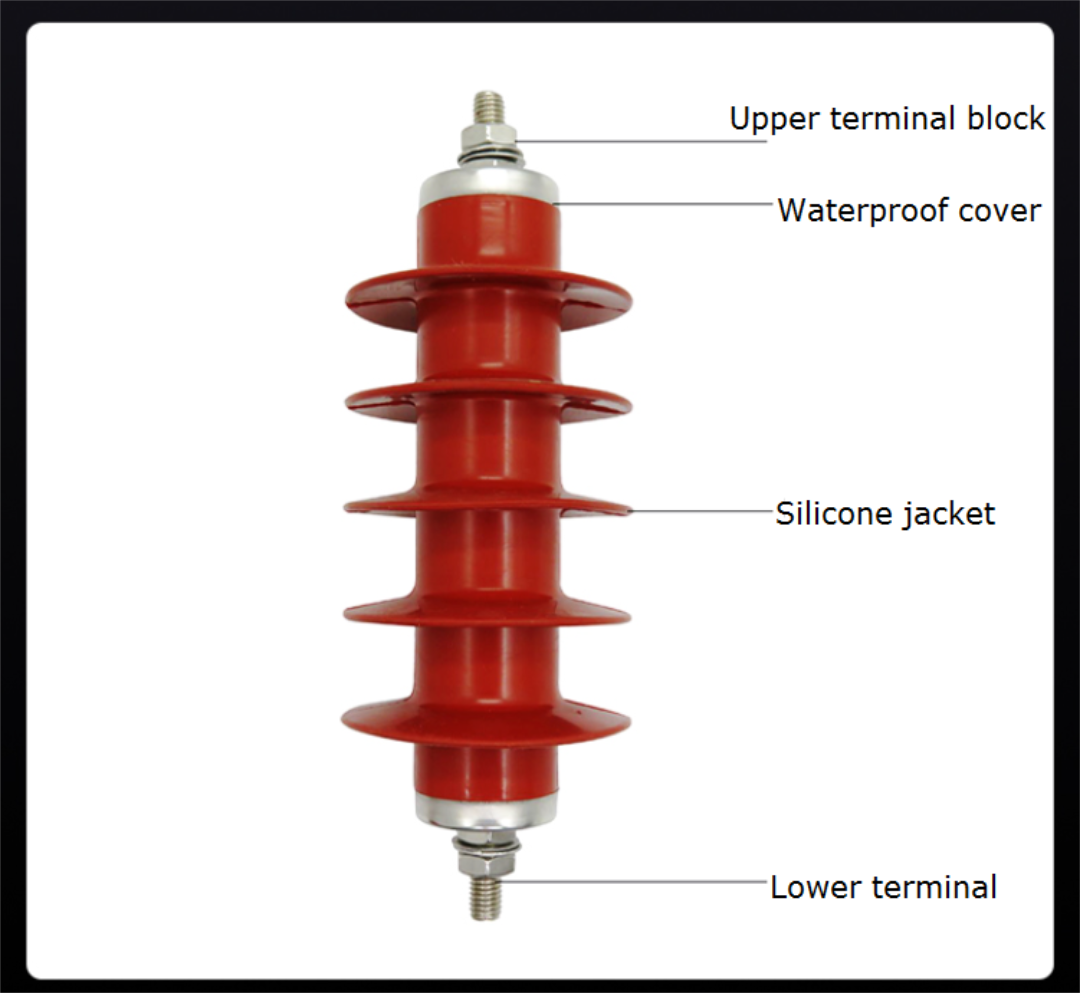

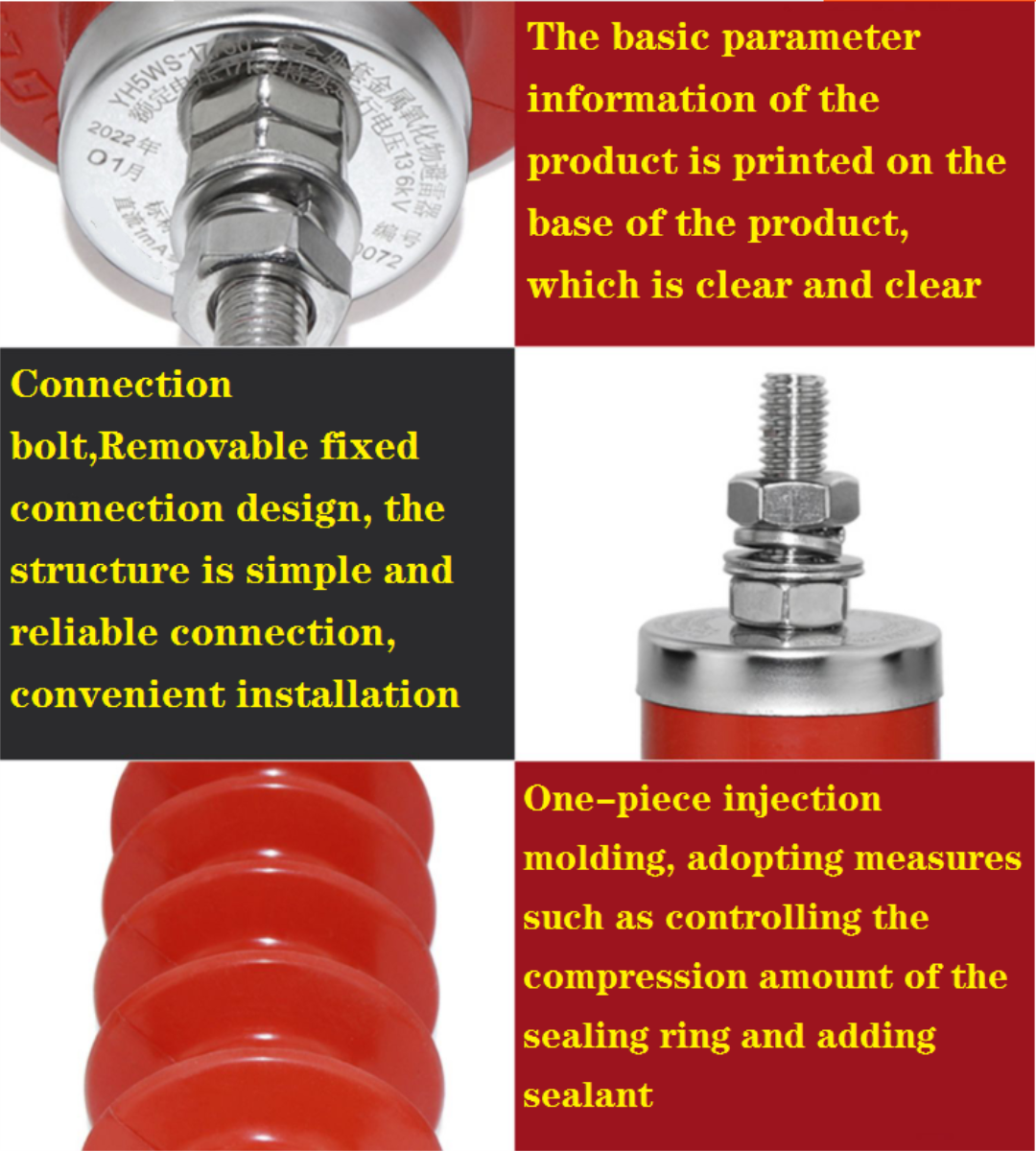

1. Small size, light weight, collision resistance, no damage to transportation, flexible installation, suitable for use in switch cabinets 2. Special structure, integral molding, no air gap, good sealing performance, moisture-proof and explosion-proof 3. Large creepage distance, good water repellency, strong dirt resistance, stable performance and reduced operation and maintenance 4. Zinc oxide resistor with unique formula, small leakage current, slow aging speed and long service life 5. The actual DC reference voltage, square wave current capacity and high current tolerance are higher than the national standard Power frequency:48Hz ~60Hz -Ambient temperature:-40°C~+40°C -Maximum wind speed: not exceed 35m/s -Altitude: not exceed 2000m -Earthquake intensity: not exceed 8 degrees -Ice thickness: not exceed 10 meters. -Long-term applying voltage does not exceed the maximum coutinuous operating voltage.

1. Small size, light weight, collision resistance, no damage to transportation, flexible installation, suitable for use in switch cabinets 2. Special structure, integral molding, no air gap, good sealing performance, moisture-proof and explosion-proof 3. Large creepage distance, good water repellency, strong dirt resistance, stable performance and reduced operation and maintenance 4. Zinc oxide resistor with unique formula, small leakage current, slow aging speed and long service life 5. The actual DC reference voltage, square wave current capacity and high current tolerance are higher than the national standard Power frequency:48Hz ~60Hz -Ambient temperature:-40°C~+40°C -Maximum wind speed: not exceed 35m/s -Altitude: not exceed 2000m -Earthquake intensity: not exceed 8 degrees -Ice thickness: not exceed 10 meters. -Long-term applying voltage does not exceed the maximum coutinuous operating voltage.

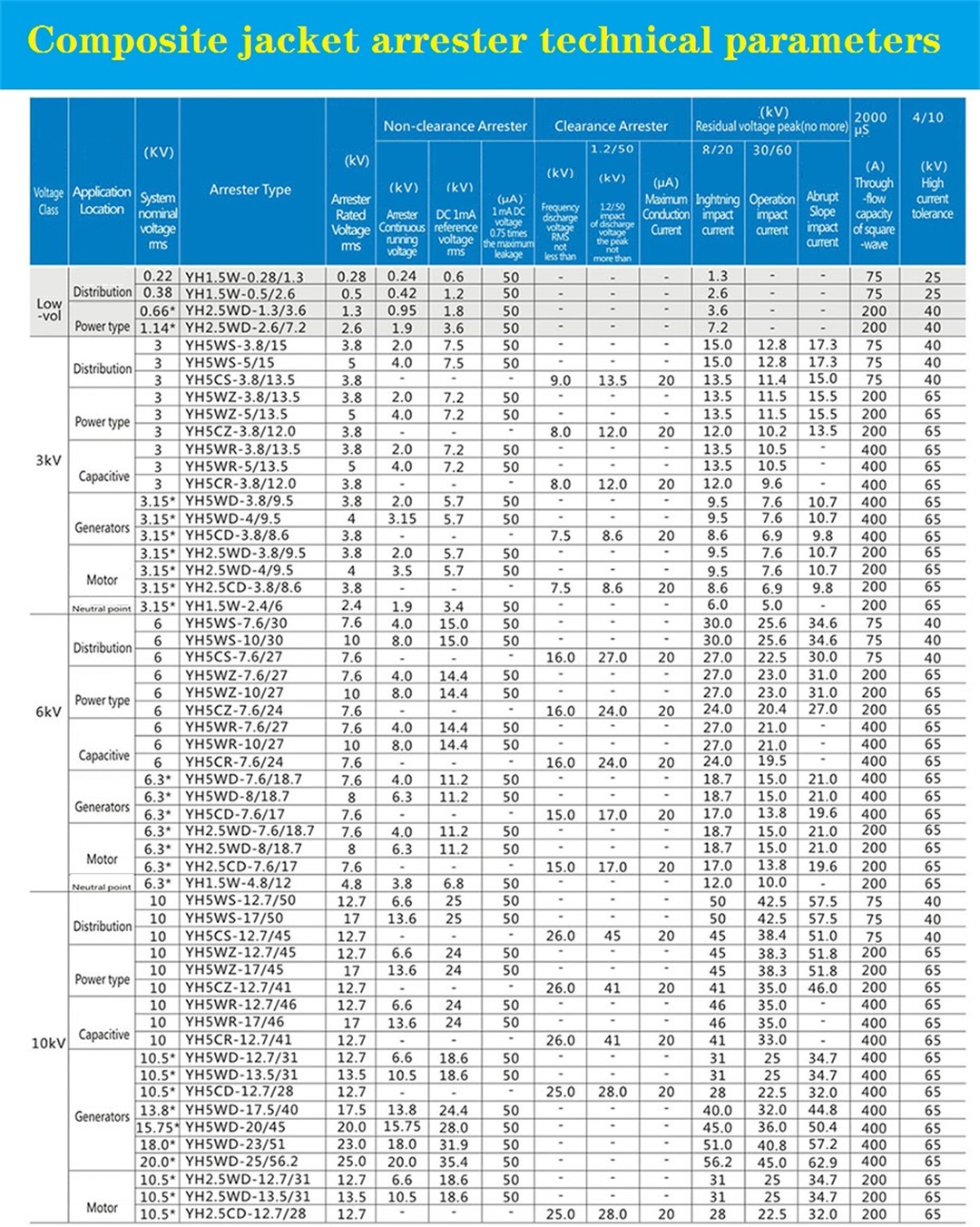

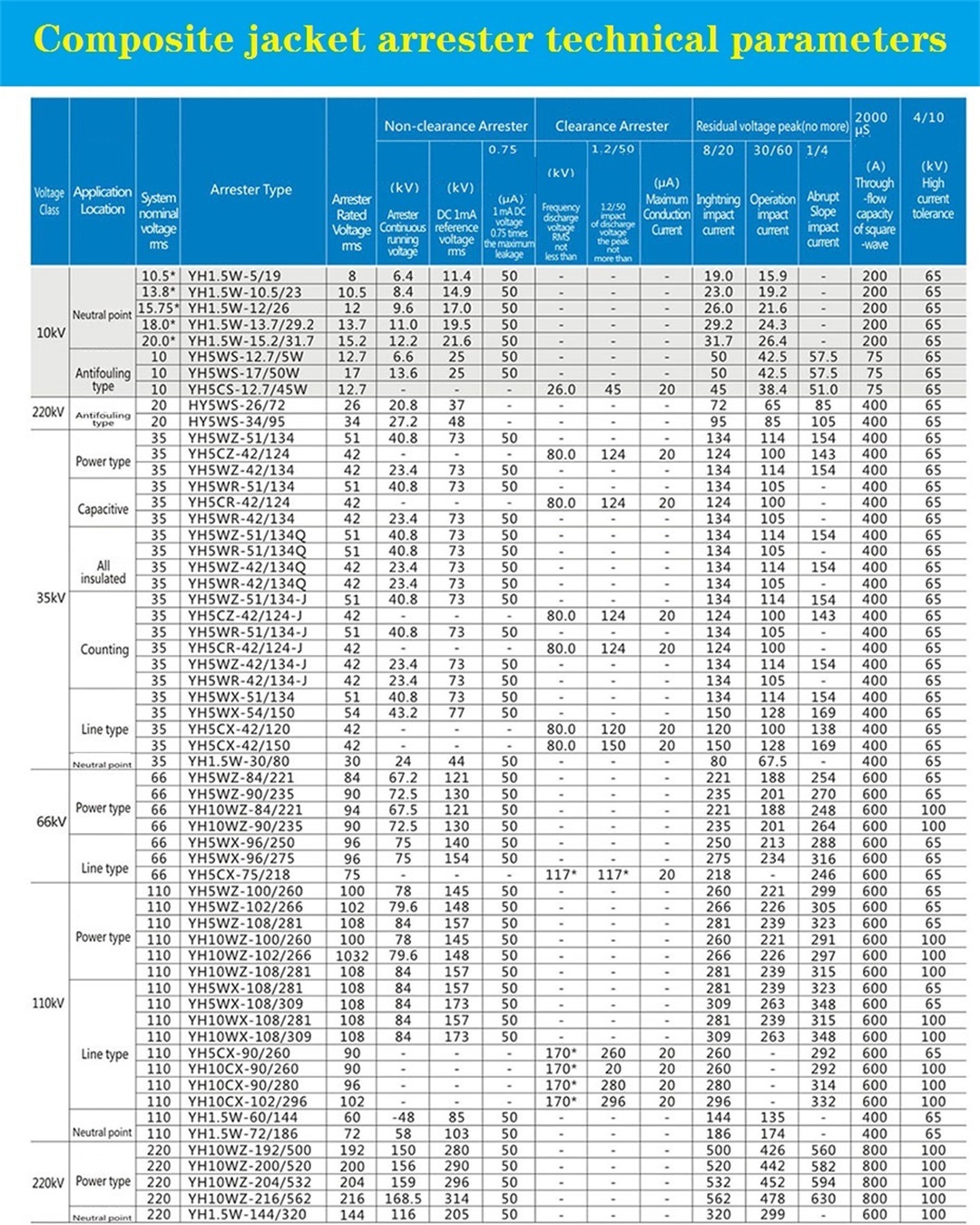

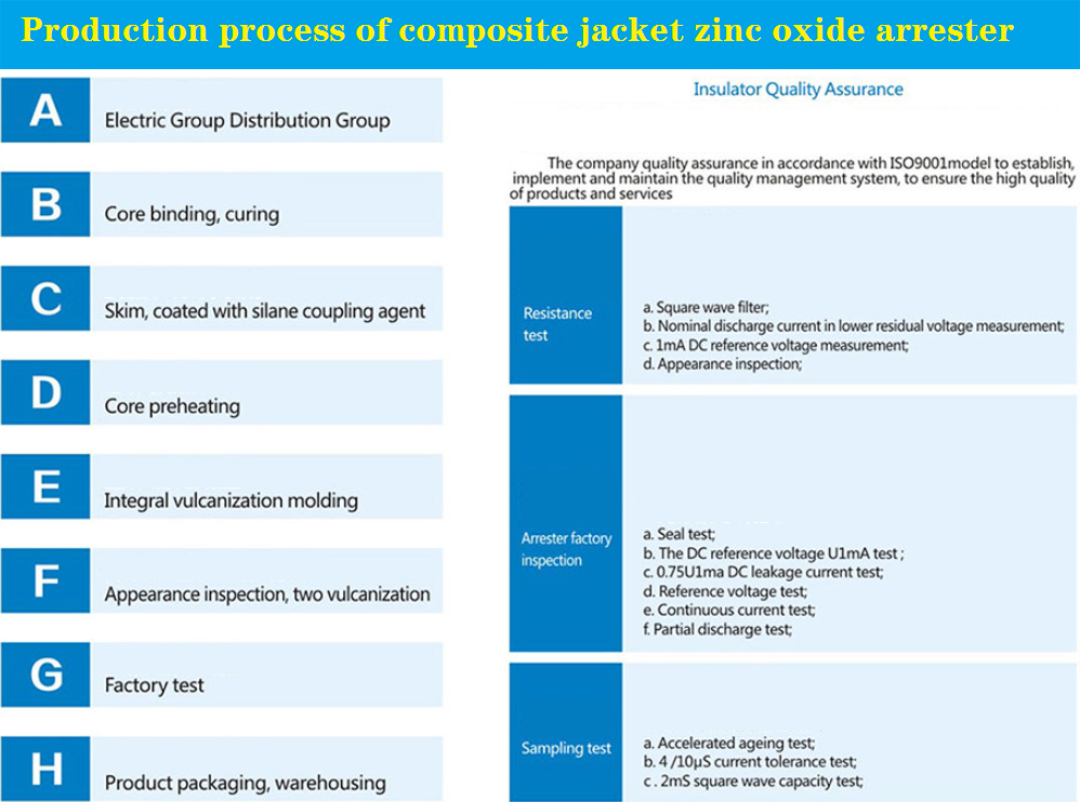

The production standard of the product is GB11032-2000 (eqv IEC60099-4:1991) "AC No-gap Metal Oxide Surge Arrester", JB/8952-2005 "Composite Jacket No-gap Metal Oxide Surge Arrester for AC System" 1. The arrester should be stored in a clean and dry room before installation and use. Must not be corroded by corrosive gases or liquids. 2. Before the arrester is put into operation, a preventive test should be carried out. After being put into operation, it should also be regularly (10KV and below arrester once every 5 years, 35KV and above arrester once every 2 years) Do the following test and compare with the data before operation with reference to the attached table: a. Measure the insulation resistance of the arrester b. Measure the DC 1mA voltage of the arrester c. Measure the leakage current of 0.75 times DC 1mA

The production standard of the product is GB11032-2000 (eqv IEC60099-4:1991) "AC No-gap Metal Oxide Surge Arrester", JB/8952-2005 "Composite Jacket No-gap Metal Oxide Surge Arrester for AC System" 1. The arrester should be stored in a clean and dry room before installation and use. Must not be corroded by corrosive gases or liquids. 2. Before the arrester is put into operation, a preventive test should be carried out. After being put into operation, it should also be regularly (10KV and below arrester once every 5 years, 35KV and above arrester once every 2 years) Do the following test and compare with the data before operation with reference to the attached table: a. Measure the insulation resistance of the arrester b. Measure the DC 1mA voltage of the arrester c. Measure the leakage current of 0.75 times DC 1mA